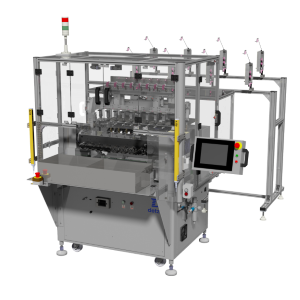

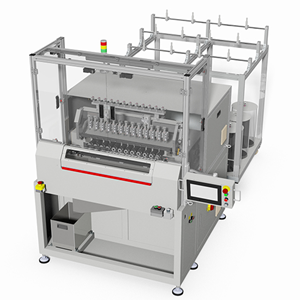

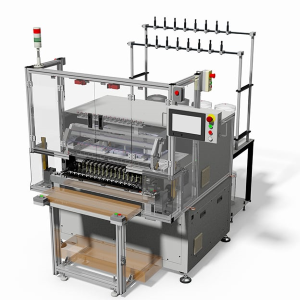

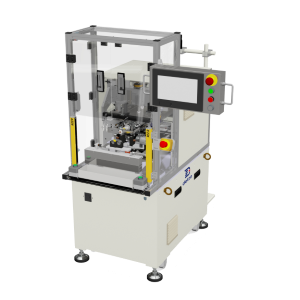

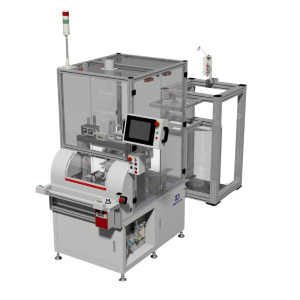

Automatic Coil Winding Machine

Advantages of DETZO Automatic Coil Winding Machine

- Multi-spindle automatic coil winder machines allow multiple winding tasks to be performed simultaneously. It effectively saves a lot of production time and improves production efficiency, which is especially important for mass production.

- Superior accuracy ensures each coil meets precise specifications and standards, reducing the risk of defective products.

- The DETZO automatic winding machine is multi-functional and can cope with various coil winding needs. Whether it is a transformer, an electric motor, an inductor, or a relay, our automatic winding machine can handle it with ease.

- Our automatic wire winding machine has a simple design, and operators can master its operation with only simple training, thus saving training time and costs.

- Advanced automation functions provide automatic coil changing, automatic adjustment of winding parameters and fault detection, eliminating the need for long-term operation and monitoring of winding tasks, thereby reducing labor cost investment.

- DETZO can provide customized coil winding machines and turnkey solutions according to customer needs to meet the needs of unmanned automatic production lines in factories.

Automatic Winding Machines FAQs

What is an Automatic Winding Machine?

Automatic winder machines use automation to wind electric coils into various electronic components, motor parts, and other related products according to the required shape, number of layers, and sizes.

How to Automatic Wire Winder Machine Work?

The principle of the automatic winding machine is to start the motion control system for winding after positioning the electric coil. The operator needs to enter the design and specifications such as the number of winding layers, the diameter of the winding, the direction of the winding, and the number of coils in the automatic winding machine control system so that the automatic winding machine can complete rotation, up and down movements and transverse movements when the winding is completed, the automatic winding machine will perform coil finishing work to ensure coil integrity and availability.

What is the purpose of automatic coil winding machines?

Automatic winding machines are mainly used to manufacture electric coils also known as coil or winding, electric coils consisting of a core and wiring that is wrapped around the core one or more enameled copper wires, usually arranged in a spiral. This working principle is when an electric current passes through the electric coil, it generates a magnetic field, and when a magnetic field passes through the electric coil the current changes in the electric coil. The electric coils are the simplest electrical components which is a key component widely used in electronic, electrical and communication devices.

What can automatic winding machines application?

-

Inductor

Electric coils are often used to manufacture various types of sensors, such as temperature sensors, pressure sensors and light sensors. They can convert changes in physical quantities into electrical signals for measurement and control.

-

It is used to regulate voltage and interchange high voltage and low voltage so that power can be transmitted and distributed effectively. It plays a key role in the power system and is one of the typical applications of electric coils.

-

The electric coil in the electric motor is used to produce rotational motion. When current passes through the electric coil, it generates a rotating magnetic field to promote the operation of the motor.

-

Communication Equipment

Electric coils are used in communication equipment such as antennas and radios to create and interpret electromagnetic signals.

-

Electronic Circuits

Electric coils play an indispensable role in electronic circuits such as filters, oscillators, and amplifiers. They are mainly used to change the characteristics of signals to achieve specific functions.

Which industries require automatic electric coil winding machines?

Automatic winding machines manufacture high-quality wires or coils in an automated manner. This precision manufacturing process helps improve product consistency, efficiency, and reliability and is widely used in various industries:

-

Electronic Product Manufacturing

Automatic winding machines can be used to wind inductors, transformers and other important electronic components to ensure the performance and reliability of these components and play a key role in manufacturing electronic products.

-

Motor Manufacturing

Motors are the core components of various mechanical equipment, and automatic winding machines are used to wind the coils of motors. This helps improve the efficiency and performance of the electric

-

Energy Industry

In the energy industry, automatic winding machines are used to wind the coils of generators to ensure the stable operation of the generators. They can also be used to manufacture solar panels.

-

Transportation

Automatic winding machines also play a key role in the manufacturing of transportation vehicles such as cars and trains. They can be used to make engines, transmissions and other critical components.

-

Wind Energy Industry

In the wind energy industry, automatic winding machines are used to wind the coils of wind turbines to ensure the efficient operation of wind turbines.

How much does an automatic winding machine cost?

DETZO provides different automatic winding machine specifications according to different spindles, pitch range, winding width, turn resolution, spindle speed, torque, wire diameter, power supply, dimensions, weight, etc. Welcome to write to us to inform us of your winding requirements and we will provide you with a detailed quotation.

What automatic winding machines does DETZO offer?

DETZO automatic winding machine types include multi-spindle coil winding machines, air-coil winding machines, flat-wire winding machines, and motor stator winding machines.

-300x300.jpg)