DIP Soldering Machine

Core Advantages of Automated Dip Soldering Machines

As a professional dip soldering machine manufacturer, DETZO designs automated dip soldering systems for electromechanical components, coils, and sensors, delivering stable, repeatable soldering results with several technical advantages:

-

Comprehensive Physical Wetting

Both flux and solder are applied via immersion. Fluid pressure and surface tension ensure that pins are uniformly coated, effectively reaching joints that are difficult for traditional methods. -

Simultaneous Multi-Point Soldering

Multiple terminals can be soldered simultaneously in a single dipping cycle. This process maintains steady output efficiency and high quality consistency. -

Stable and Sufficient Heat Transfer

The molten solder bath provides stable thermal capacity, ensuring terminals or windings reach the required temperature rapidly to form a reliable alloy bond. -

Precise Stroke and Depth Control

High-precision servo systems control the dipping depth, preventing excess flux or solder creep to maintain component insulation and cleanliness.

DETZO’s Flexible Configurations: From Development to Production

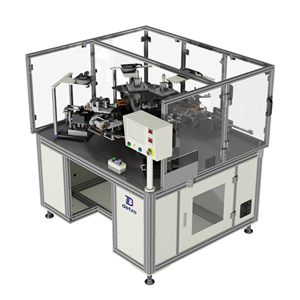

01. Benchtop Type

Ideal for: Small batches, prototyping, and lab development.

Highlights: Compact design with industrial precision. Digital temperature and stroke settings ensure development parameters align with future production needs.

02. Standalone Automation

Ideal for: Standard production and consistent processes.

Highlights: Integrated flux and solder workflow with automatic dross management. A stable choice for achieving consistent process results.

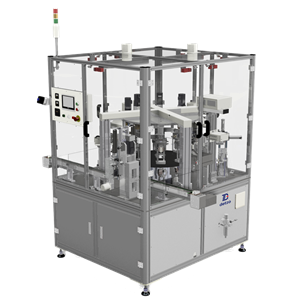

03. Multi-station Integrated Cell

Ideal for: High-capacity requirements and smart manufacturing.

Highlights: Parallel station design integrates fluxing, pre-heating, soldering, and CCD inspection for comprehensive process control and traceability.

Why Choose DETZO DIP Soldering Machines?

- Integrated R&D Mindset: Combining our understanding of coil characteristics with precise thermal control, we achieve stable soldering while minimizing impact on fine wires.

- Data-Driven Production: We provide traceability for key parameters, offering reliable data support for customers in automotive and communication industries.

- Process Optimization: We design specialized jigs and adjust fluid dynamics for different products to overcome challenges such as air bubbles or uneven soldering.

Scalable Dip Soldering Solutions for Reliable Manufacturing

From lab-scale Benchtop units to Multi-station CCD-integrated lines, DETZO offers comprehensive technical support for dip soldering. By combining thermal management with vision technology, we help customers maintain a quality edge through steady processes and achieve competitive production goals.