Valve

Valves are the essential mechanical "gates" used to regulate, direct, or control the flow of fluids—whether water, oil, or air. Unlike specialized high-speed electronic solenoids, general-purpose valves in appliances and pumps focus on mechanical durability, chemical resistance, and sealing integrity under pressure. From the intake valve of a washing machine to the lubrication oil valves in heavy machinery, the core performance is defined by the precise assembly and robust actuation of the valve mechanism.

DETZO specialized in automated manufacturing solutions for various valve components. We provide high-precision assembly and specialized winding equipment for valve actuators, ensuring that every unit meets the stringent leakage and operational lifespan standards required by global OEM brands. For expert valve production technology, please Contact DETZO.

Think of a valve as a "traffic controller" for fluids. While a switch controls electricity, a valve manages physical mass—often under high pressure or varying temperatures.

The Battle Against Friction: In pumps and oil valves, internal components are constantly subjected to friction and fluid erosion. If the actuating motor or coil is not perfectly balanced during production, it leads to "Cavitation"—tiny bubbles that can erode metal. Precision manufacturing is the key to preventing this mechanical fatigue.

The Art of Sealing: A valve's primary job is to stop leaks. This requires an exact force to press the seal into the seat. DETZO ensures that the electromechanical force generated by the coil is consistent across every batch, providing a "Zero-Leak" guarantee for household and industrial systems

Modern valves take diverse forms to handle everything from domestic water to industrial lubricants:

01. Appliance Water Valves

Style: Compact plastic bodies with rubber diaphragms, common in washing machines and dishwashers.

Description: Must withstand thousands of city water pressure cycles. Precision coils smooth the closing action to prevent "Water Hammer" vibrations.

02. Pump Control Valves

Style: Robust metal or high-grade polymer valves integrated into water or fuel pump housings.

Description: Maintains back-pressure or prevents reverse flow. Requires high thermal stability coils to operate near hot motors without performance loss.

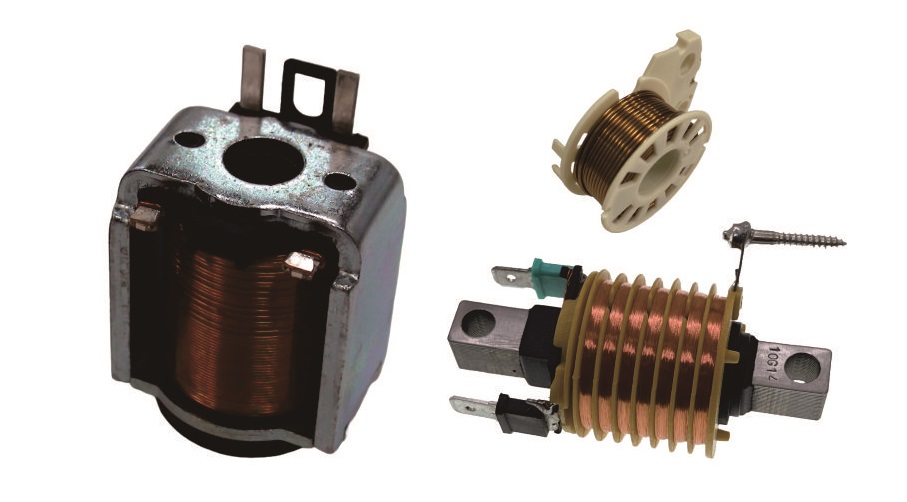

03. Mechanical Oil Valves

Style: Precision-machined steel valves found in hydraulic systems or automotive lubrication lines.

Description: Designed for high-viscosity oils. Requires high-torque actuation to overcome lubricant resistance, demanding heavy-duty coil winding.

04. Electronic Expansion Valves (EEV)

Style: Precision needle-valve structure driven by a stepping motor coil, often encapsulated in a stainless steel housing.

Description: Critical for HVAC and EV thermal management. It regulates refrigerant flow with micron-level precision to maximize cooling efficiency.

05. Pressure Relief & Safety Valves

Style: Spring-loaded or pilot-operated heavy-duty valves with reinforced solenoid triggers.

Description: A safety component that opens when pressure exceeds limits. Production precision is critical—the coil must provide instant, high-force activation even after years of dormancy.

The valve industry is evolving toward smarter, more responsive designs:

Smart Fluid Metering

Integrating sensors within valves for precise flow tracking in smart homes and IoT factories.

Eco-friendly Sealing

Using new composite materials that reduce friction and energy loss during long-term operation.

Compact High-Pressure

Miniaturizing valves while handling high-pressure environments in new EV thermal systems.

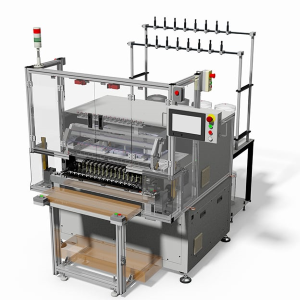

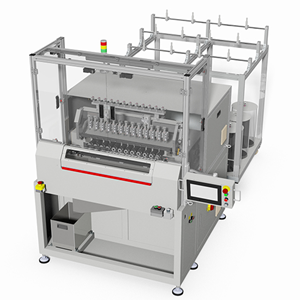

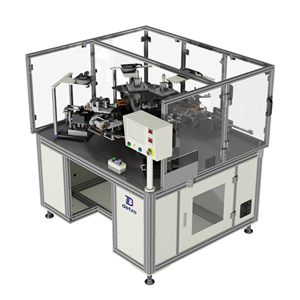

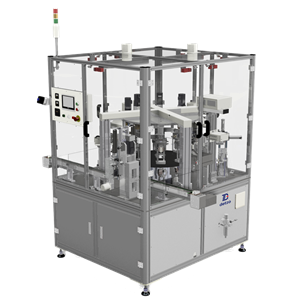

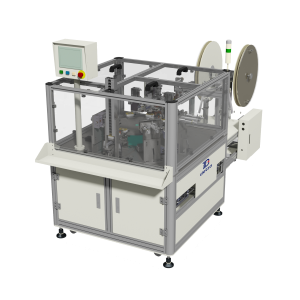

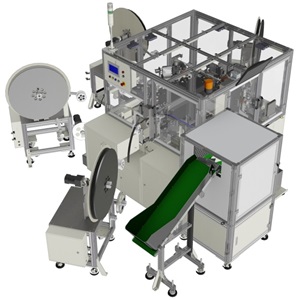

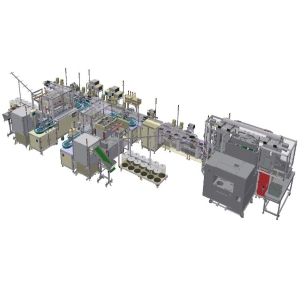

Automated Production Solutions for High-Performance Valve Actuation

A Valve is a critical mechanical system designed to regulate the flow, direction, and pressure of fluid media. As global industries transition toward smart mobility and automated fluid management, the Electrification of Valves has become a decisive factor in performance. The reliability of a modern valve—whether it is a simple shut-off or a complex proportional control valve—fundamentally depends on the electromagnetic consistency, thermal stability, and mechanical precision of its actuation core.

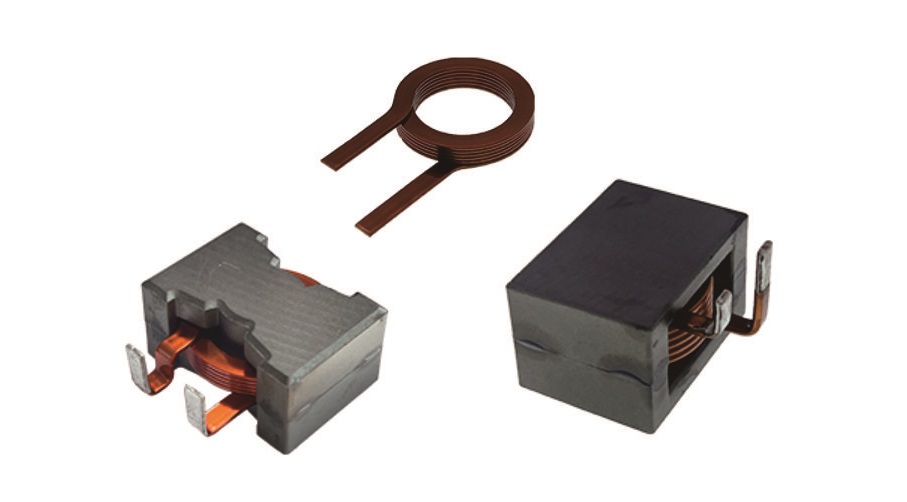

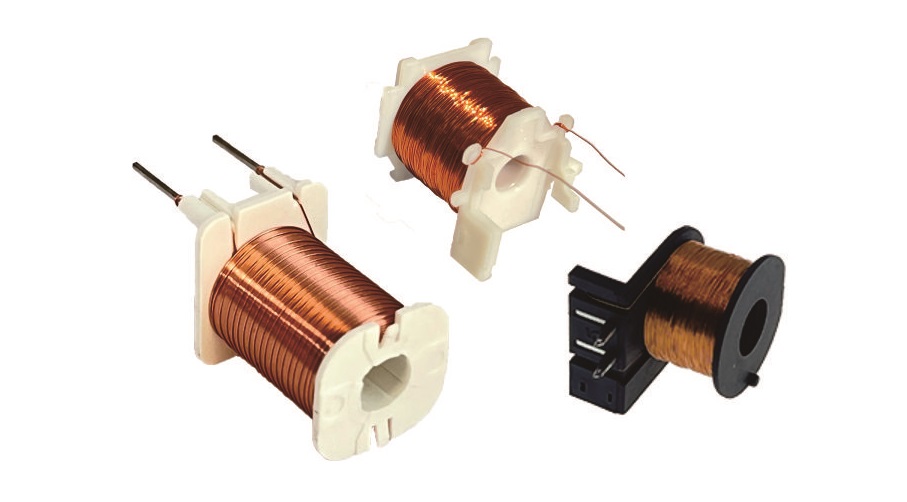

The actuator coil is the "motor" that drives the valve's mechanical movement. DETZO provides specialized automation systems tailored to the unique requirements of various valve types:

01. Precision Pulse & Stepping Actuators

- Valve Types: Electronic expansion valves (EEV), micro-metering valves, and fuel injectors.

- Engineering Focus: Ensuring ultra-precise winding tension to stabilize the millisecond response required for fine fluid regulation.

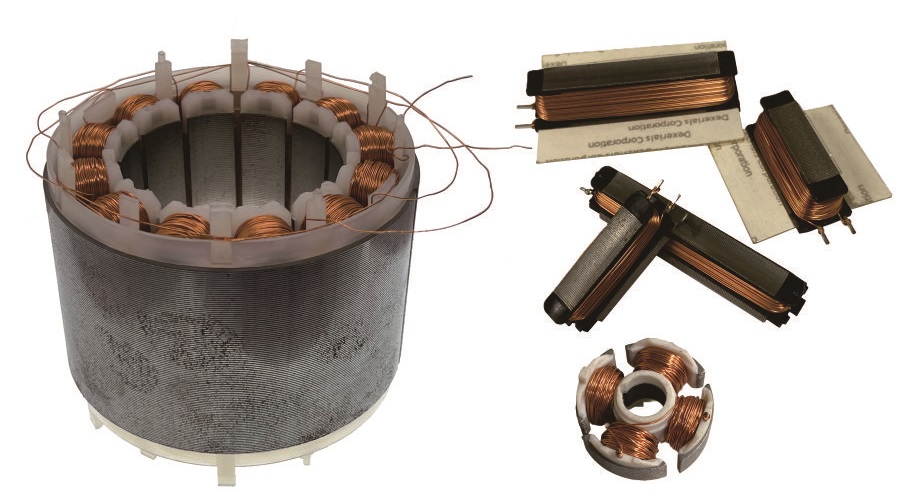

02. Heavy-Duty Industrial Valve Actuators

- Valve Types: High-pressure hydraulic valves, oil & gas pipeline valves, and process control valves.

- Engineering Focus: Maximizing copper density within the coil to ensure powerful mechanical force and superior heat management under continuous load.

03. Specialized High-Density Actuators

- Valve Types: Aerospace control valves and high-precision medical sensing valves.

- Engineering Focus: Micro-wire handling technology for high-torque output within extremely compact valve envelopes.

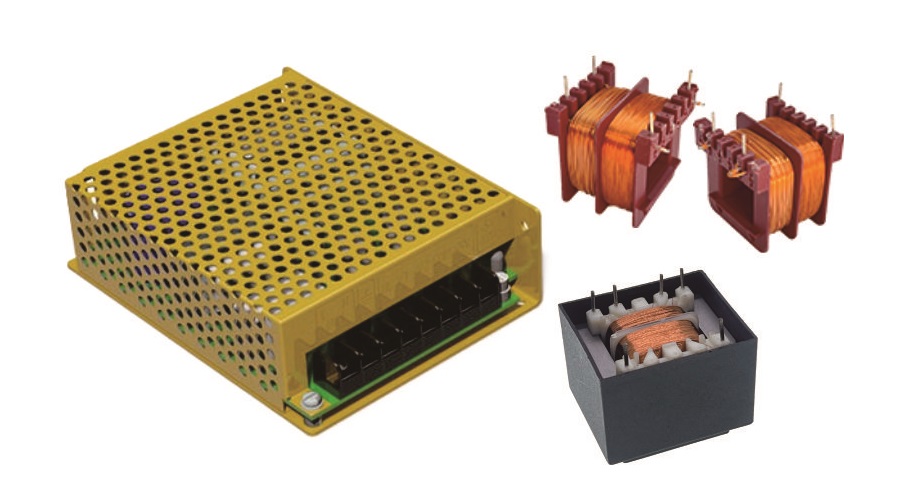

01. Optimized Mechanical Performance:

Precision-wound actuators provide a uniform magnetic field, which is essential for the smooth, linear movement of valve stems and plungers.

02. Robust Component Integrity:

Integrated laser stripping and precision soldering guarantee low-resistance electrical joints that can withstand vibrations and thermal shocks.

03. Compliance & Traceability:

Real-time logging of critical production data ensures that every valve meets international safety and quality standards, including IATF 16949.

DETZO delivers the engineering expertise necessary for high-precision electromagnetic component production. We offer comprehensive design consulting and global support to ensure your manufacturing processes achieve optimal technical compliance. Please feel free to Contact DETZO.