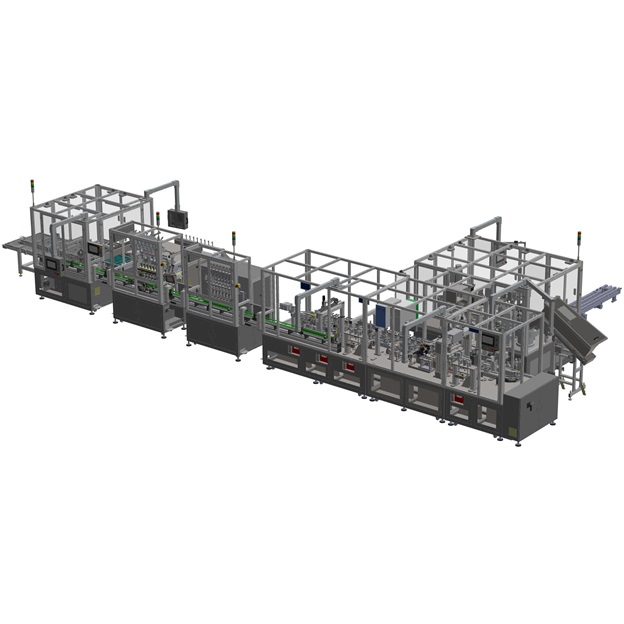

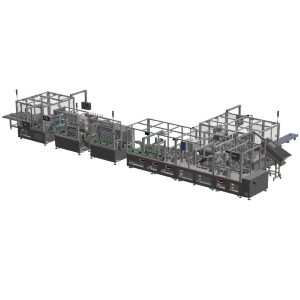

Automotive Coil Assembly Production Line

Automotive Coil: Automated Assembly Line

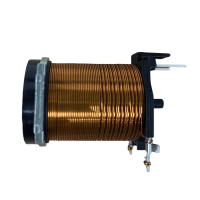

DETZO's custom automotive coil automation solution integrates the entire manufacturing process, from bobbin feeding and precision winding to iron plate riveting. Designed with a high-stability synchronous control system, it meets the rigorous demands of automotive electronics for extreme precision and durability.

Automated Feeding

Utilizing a tray-type automatic bobbin feeder for precise component orientation and continuous automated loading.

Winding & Insulation

Combining the DSW-8008NPC winding machine and DSW-TP8008 taping machine for high-performance insulation.

Spot Welding & Test

A specialized spot welding tester performs terminal joining and performance validation for maximum stability.

Riveting & Inspection

The rotary iron plate riveting tester executes physical assembly while conducting full quality inspection.

Output & Integration

The finished product output station sorts qualified parts for seamless integration with downstream processes.

Integrated automotive processes for zero-defect production

DETZO Turnkey Solutions

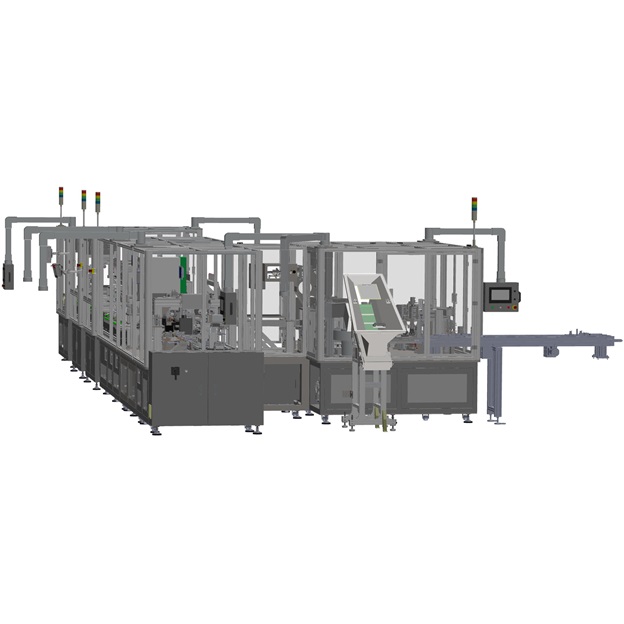

Automotive Coil: Production Flow

STEP 01 | Automatic Feeding

- A. Tray-type bobbin feeder - Automated orientation and feeding

STEP 02 | Winding & Taping

- B. DSW-8008NPC Auto winding machine - High-precision multi-axis winding

- C. DSW-TP8008 Auto taping machine - Automated insulation taping

STEP 03 | Welding & Testing

- D. Spot welding tester - Terminal welding and continuity verification

STEP 04 | Riveting & QC

- E. Rotary riveting tester - Component assembly and full QC inspection

STEP 05 | Output Terminal

- F. Finished product output - Collection and downstream integration