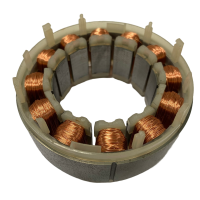

3 Phase BLDC Motor Winding Machine

FDM-3002L

Applications

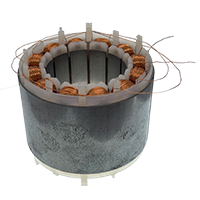

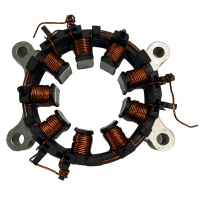

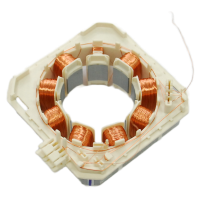

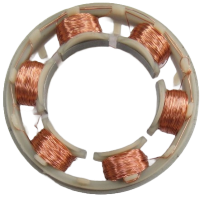

The DETZO FDM-3002L is a precision automated winding machine designed for high-quality In-slot Stators (Inner Winding). Supporting a maximum stator outer diameter of 130mm and utilizing advanced Needle winding technology, it specializes in the high-performance winding of internal rotor motors. With enhanced servo motion travel and stable tension control, the FDM-3002L achieves superior fill factors and quality consistency even within complex slot geometries, making it the ideal choice for mass-producing medium-to-large industrial and drive motors.

Stator max. O.D. : 130mm

Feature

High-Torque Smart Winding System: Integrating Keyence control technology with a 3KW high-power servo motor and a 4:1 precision gear reducer. Engineered for premium stability and winding accuracy, featuring automated wire clearing and 120-program memory to balance low maintenance with high-efficiency output.

Exact Positioning: Combines Keyence systems with AC servo drives for millisecond-level precision control.

Dialogue HMI: 10" interface with conversational mode for intuitive and effortless program editing.

Powerful Torque: Features a 3KW servo motor with a 4:1 gear reducer for high-torque stability and rotation accuracy.

Auto-Process: Automated pin wrapping and wire clearing ensure a clean process with zero residual wire.

Security Logic: Hierarchical access and password protection prevent unauthorized changes to maintain process integrity.

Flexible Output: Stores 120 programs with a simple structure designed for rapid changeovers and low maintenance.

Technical Specifications

No. of Spindle

2 Spindles (Pitch 300mm)

Spindle Speed

Max 500 rpm (CW/CCW)

Wire Diameter

Ø0.20 ~ Ø1.00mm

Control System

PLC 5-axis control

| Nozzle Movement | X: 195 / Y: 235 / Z: 175 mm | Positioning Accuracy | Disp: 0.01mm / Angle: ±0.5° |

|---|---|---|---|

| Max Stator O.D. | 130mm | Stator Height | 10 ~ 70mm (Incl. Insulator) |

| Power Supply | 3Φ 220Vac | 50 ~ 60Hz ±1% | Data Storage | Memory Card |

| Power Consumption | 9.0KW | Air Requirement | 0.4 ~ 0.6Mpa |

| Machine Weight | 600kg ±10 | Machine Dimensions | 1508(L) x 926(W) x 1550(H)mm |

Optional Accessories

CE Certification

Safety Guard

Wire Breakage Detection

Cutter Mechanism

Tension released mechanism