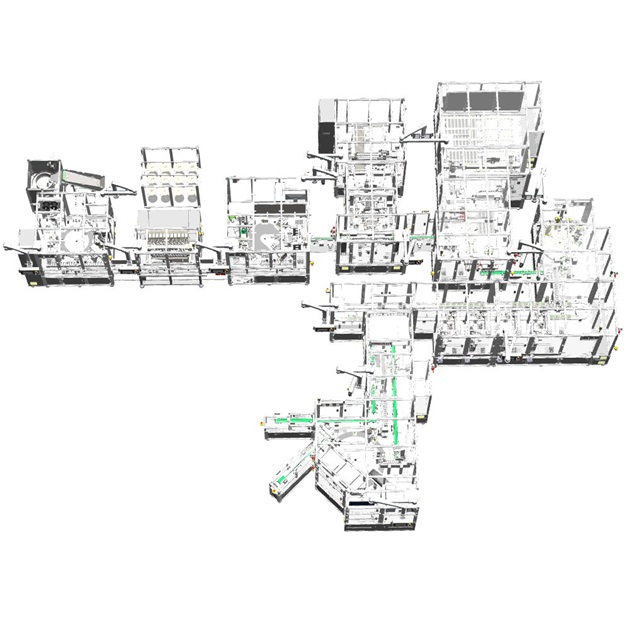

Motor Stator Coil Assembly Production Line

Motor Stator: Automated Assembly Line

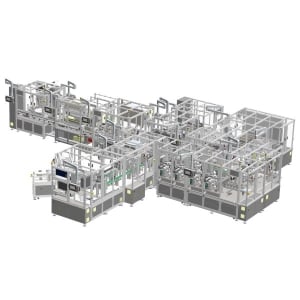

The DETZO Motor Stator Coil Production Line is designed for high-precision motor core components. This system integrates automated pin insertion, precision winding, and unique dual-core assembly technology. Through synchronized inspection and spot welding processes, we ensure every stator coil meets the highest standards in electrical performance and mechanical structure.

Feeding & Pinning

Automated bobbin feeding via vibrating plate, with 8-station pin inserting for precision terminal forming.

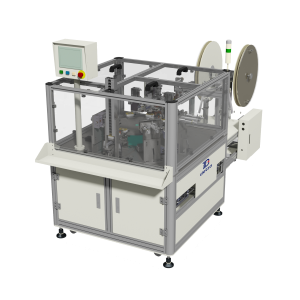

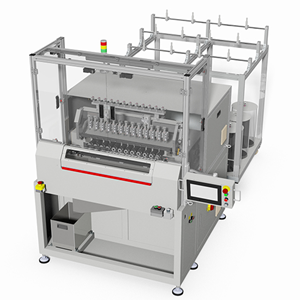

Winding & Testing

High-efficiency winding using the DSW-6012PN, followed by 8-station soldering/testing for quality assurance.

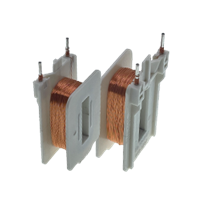

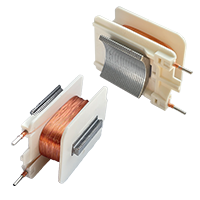

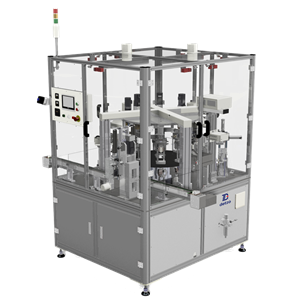

Dual-Core Assembly

Integrated inner and outer core assembly machines for precise nesting and positioning of the stator structure.

PCB & Spot Welding

Component integration via rotary PCB assembly and fine circuit connection using iron spot welding.

QC & Output

Full inspection via 8-station assembly tester, manual rework station support, and final output system.

Synchronizing core assembly with precision inspection

DETZO Turnkey Solutions

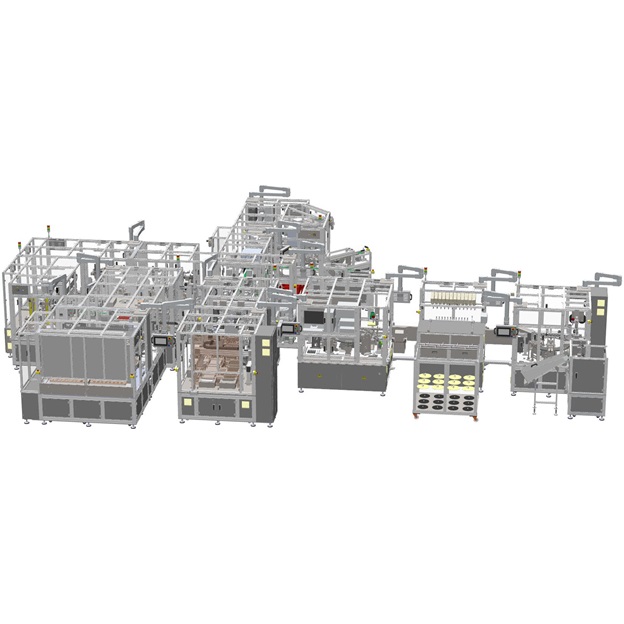

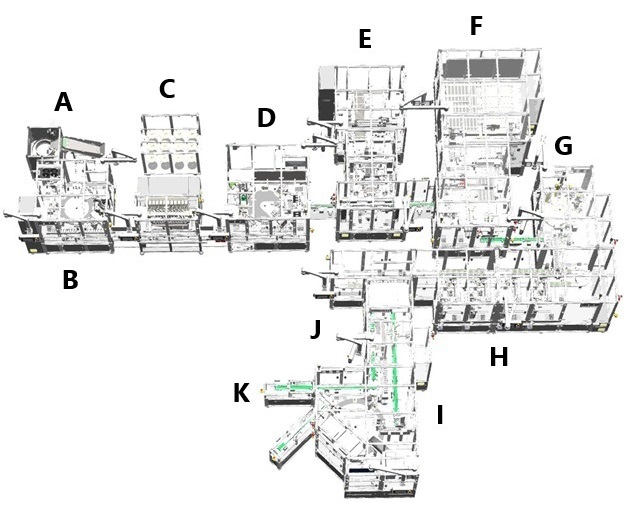

Motor Stator Coil Assembly: Production Flow

STEP 01 | Bobbin Loading & Pin Inserting

- A. Vibratory Bowl Bobbin Feeder

- B. 8-Station Pin Inserting & Cutting Machine

STEP 02 | Precision Winding & Soldering

- C. DSW-6012PN Auto Winding Machine

- D. 8-Station Soldering & Testing Machine

STEP 03 | Dual Iron Core Assembly

- E. Small Core Assembly Machine

- F. Large Core Assembly Machine

STEP 04 | PCB Mounting & Spot Welding

- G. Rotary PCB Assembly Machine

- H. Soldering Iron Spot Welder

STEP 05 | Final Inspection & Output

- I. 8-Station Assembly Testing Machine

- J. Manual Inspection & Rework Station

- K. Finished Product Output

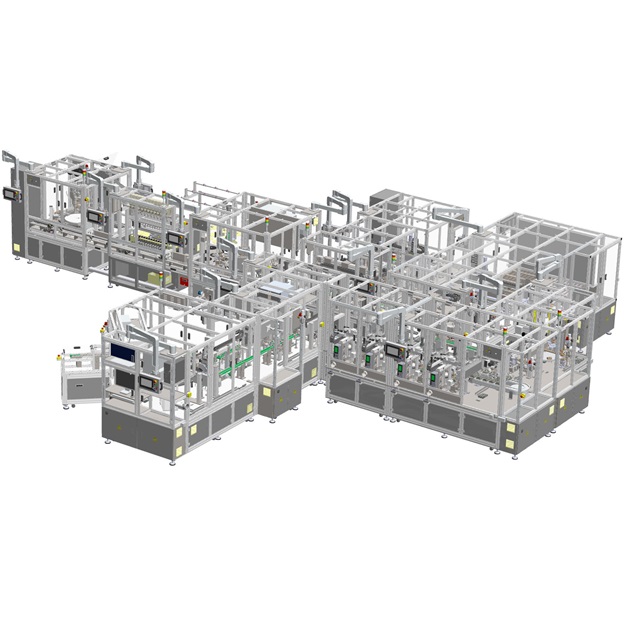

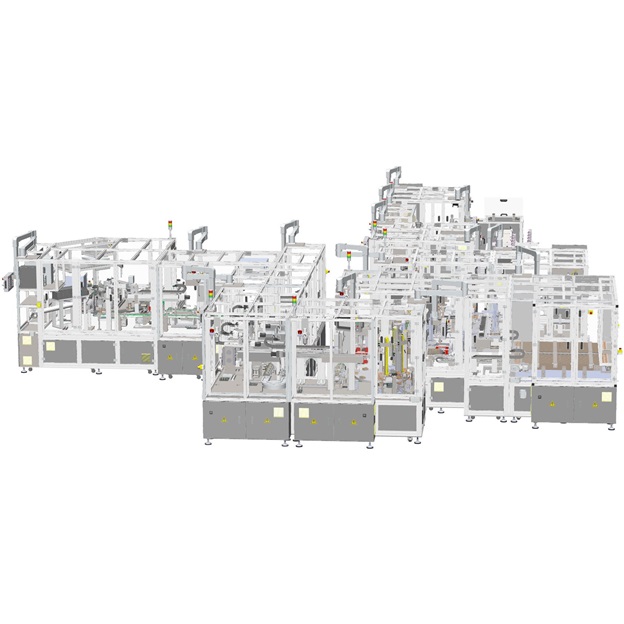

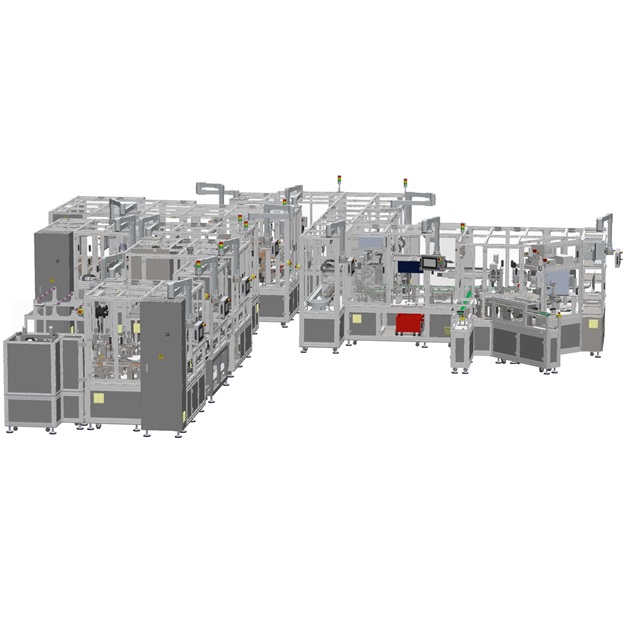

▲ Production Line Equipment Layout (Station A-K Correlation)