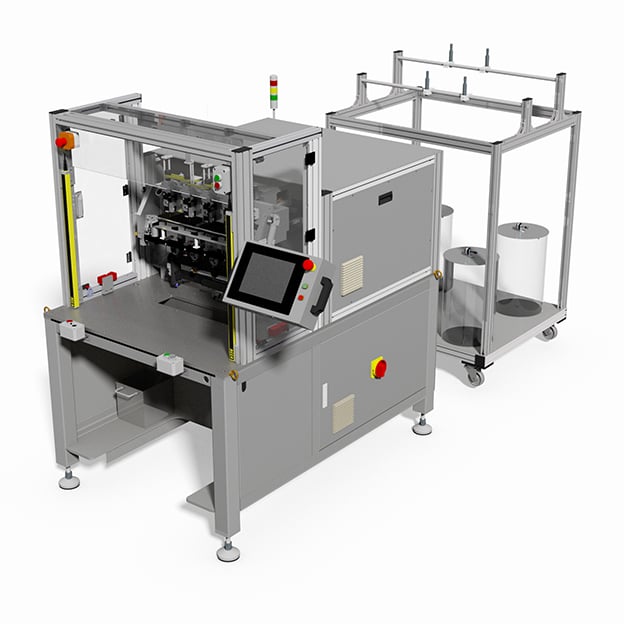

DSW-12004PNC Automatic Coil Winding Machine

DSW-12004PNC

Feature

Precision Drive Control

Integrated Keyence systems and AC servo motors ensure high-precision positioning.

Intuitive HMI

10" HMI with conversational programming for user-friendly and efficient operation.

Advanced Winding Tech

Auto terminal winding and wire clearing with 0°, 90°, and 120° angle settings.

Quick-Change Tooling

Unique winding fixtures designed for rapid installation and reduced downtime.

Automated Productivity

Auto loading/unloading functionality optimizes throughput and ensures zero residue.

Smart Data Management

Stores 120 programs with hierarchical password protection to prevent errors.

Robust Maintenance

Simple mechanical structure for easy control and low-effort daily maintenance.

Technical Specifications

No. of Spindle

4 Spindles (120mm pitch)

Max. Speed

9,000 rpm

Wire Diameter

Ø0.02 ~ Ø1.00 mm

Control System

PLC 4-Axis Servo Control

| Nozzle Movement | X: 190 / Y: 150 / Z: 80 mm | Positioning Accuracy | Disp: 0.01mm / Angle: ±0.5° |

|---|---|---|---|

| Winding Range | Max. Dia: 100mm / Max. Width: 90mm | Wrapping Angle | 0°, 90°, 120° |

| Infrastructure | 3Φ 220Vac | 50~60Hz | 0.4~0.6Mpa | Power Consumption | 4.5KW |

| Storage Method | Memory Card | Machine Weight | 1000kg ±10 |

| Machine Dimensions | 1600(L) x 1100(W) x 1800(H) mm | ||

| Twisting Spec (Opt.) | Wire: Ø0.03~0.15mm / Length: 300mm | Twisting Performance | Turns: 1~9T / Speed: 6,000rpm |

| Taping Spec (Opt.) | Outer Dia: Ø50~130mm / Width: 2~20mm (Please contact us if it exceeds the usage range) | ||

| Stripping Spec (Opt.) | Wire Diameter: Ø0.20 ~ Ø1.20mm | ||

Optional Accessories

CE Certification

Safety Guard

Bifilar winding

Wire Breakage Detection

Hot Air Bonding Mechanism

Wire Stripping Mechanism

Twisting Mechanism

Taping Mechanism

Wire Hooking (Pressing) Mechanism

Cutter (Nipper) Mechanism

Tailstock Mechanism

Tension released mechanism

Servo Wire clamper Mechanism

Servo Loading/Unloading Mechanism