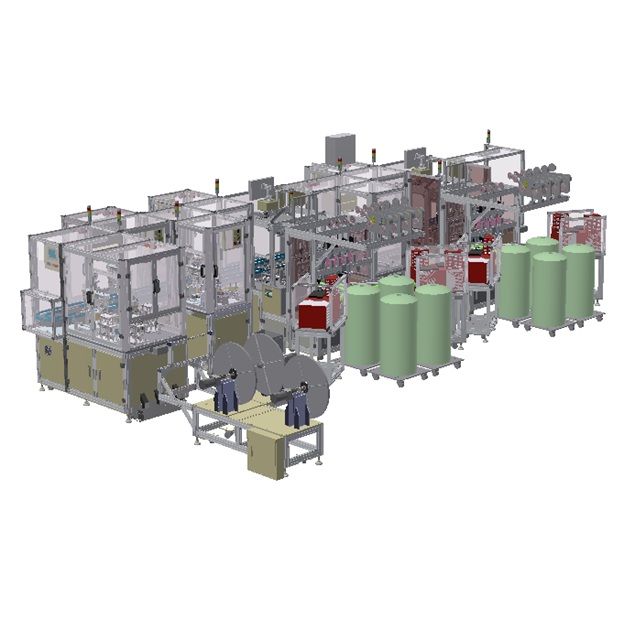

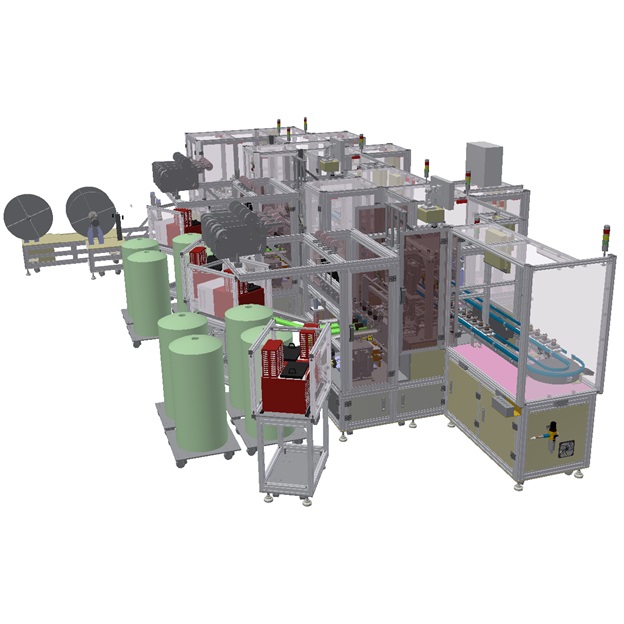

Starting Coil Production Line

Customized model 10

Starter Coil: Automatic Production Line

The DETZO Starter Coil Automatic Production Line is specifically engineered for starter coils, featuring a dual-station vertical winding system for both thick and thin wires. This line integrates precision spot welding, pin insertion, and 100% resistance testing for high-volume, defect-free production.

Integrating dual-winding technology with precision QC testing

DETZO Turnkey Solutions

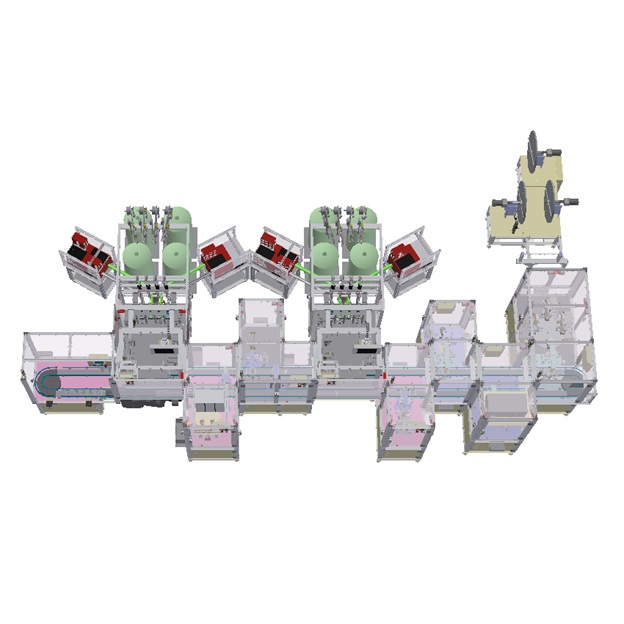

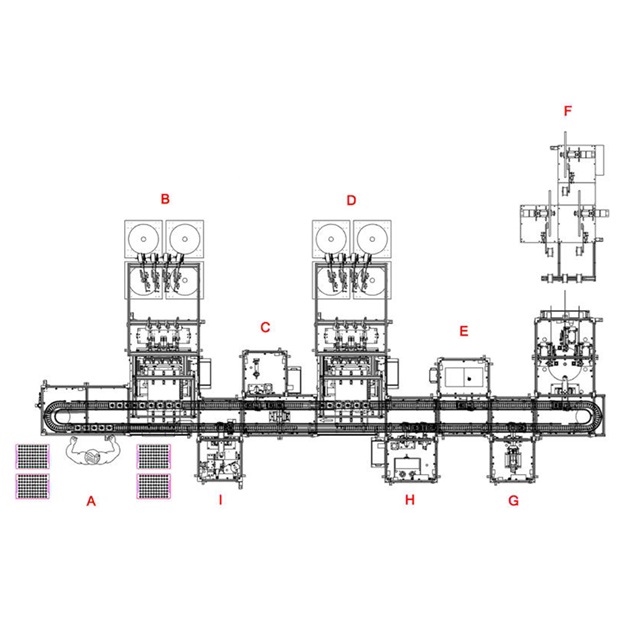

Starter Coil: Production Process Flow

STEP 01 | Loading & Primary Winding

- A. Manually loading / unloading station

- B. Vertical automatic coil winding machine (thick wire)

- C. With or without winding detection station

STEP 02 | Precision Winding & Assembly

- D. Vertical automatic coil winding machine (thin wire)

- E. Automatic spot welding mechanism

- F. 4-station pin inserting machine

- G. Copper wire cutting station

STEP 03 | Testing & Finishing

- H. Resistance testing station

- I. Taping mechanism