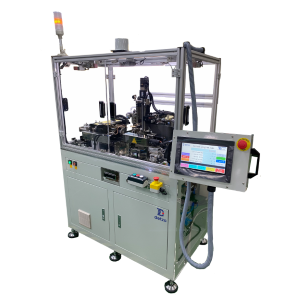

Air Coil Winding Machine

Core Advantages of Air-Coil / Bobbinless Winding Machines

Air-coils feature a bobbinless design that reduces weight and optimizes space, making them vital for high-precision sensors and inductors. DETZO’s air coil winding machine provides several technical advantages:

-

Precision Forming & Geometric Consistency

Advanced tooling and precision displacement control ensure exact dimensions and turn counts even without a physical bobbin, meeting the strict requirements of miniaturized components. -

Diverse Self-bonding Technologies

Supports multiple bonding methods including hot air, alcohol, and electric heating, ensuring uniform interlayer adhesion and structural integrity. -

Multi-axis Synchronized Motion

Capable of winding circular, rectangular, and complex irregular shapes with a high filling factor through precise servo algorithms. -

Superior Quality Factor (Q) Maintenance

By eliminating the bobbin medium, these coils achieve high electrical performance and low parasitic capacitance, enhancing high-frequency stability.

Three Self-bonding Configurations: Adaptable to Diverse Processes

01. Hot Air Bonding

Ideal for: Standard precision coils and acoustic components.

Technical Highlights: Precise temperature-controlled air melts the coating during winding, providing a clean environment and stable bonding strength.

02. Alcohol / Solvent Bonding

Ideal for: Ultra-fine wires and temperature-sensitive sensors.

Technical Highlights: Softens the coating at room temperature using a solvent drip, avoiding thermal stress—perfect for processing extremely fine wires.

03. Electric / Resistance Bonding

Ideal for: Thick wire gauges and high-strength structural coils.

Technical Highlights: Utilizes resistance heat from an electrical current for highly efficient bonding with deep penetration, ensuring uniform structural strength throughout the coil.

High-Precision Process Control: The Key to Steady Production

- Precision Geometric Dimension Control: Sophisticated jig design and servo motion control manage ID/OD and thickness, ensuring consistency after forming.

- Active Tension Compensation: Real-time feedback and adjustment of winding tension prevent coil deformation or coating damage.

- Production Data Management: Records temperature, tension, and winding parameters for every coil, supporting production tracking and process stability.

Why Choose DETZO Air-Coil Winding Solutions?

- Specialized Tooling R&D: Custom de-molding mechanisms and forming tools ensure scratch-free results and efficient release for automated production.

- Highly Integrated Automation Design: Combine winding, bonding, and functional electrical testing into a single automated station for enhanced efficiency.

- Extensive Material Expertise: Decades of experience in handling ultra-fine wires, flat wires, and various self-bonding wire grades to shorten your pilot production cycle.

Commitment to Enhancing Your Production Value

From hot air and alcohol to electric resistance bonding, DETZO provides flexible and robust air-coil winding machine solutions. By combining high-precision motion control with rigorous process monitoring, we empower customers to achieve high-quality, high-efficiency automated production in the acoustic, communication, and medical industries. Contact us without hesitation!