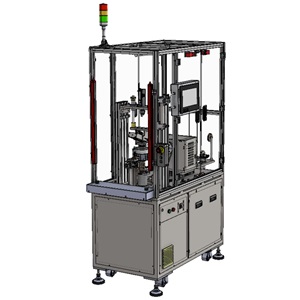

Motor Stator Winding Machine

BLDC (Brushless DC Motor) Advantages

-

High Efficiency

The absence of brushes reduces frictional energy loss, resulting in superior operational efficiency, especially at high loads and speeds. -

Low Noise and Vibration

The brushless design minimizes mechanical friction and electromagnetic interference, ensuring quiet and stable operation—ideal for household appliances and precision equipment. -

Extended Lifespan

With no brushes or commutators to wear out, mechanical losses are drastically reduced, offering a lifespan significantly longer than traditional brushed motors. -

Enhanced Reliability

No need for regular brush replacement, and spark-free operation makes BLDC motors ideal for applications requiring high safety standards. -

Exceptional Control Performance

Offers precise speed and position control, enabling smooth variable-speed adjustments for high-performance equipment. -

Energy Efficiency and Environmental Friendliness

Efficient operation reduces energy consumption, aligning with eco-friendly and energy-saving goals. -

Compact Design with High Power Density

Smaller and lighter than equivalent brushed motors, BLDC motors are perfect for space-constrained applications like electric vehicles and drones. -

Versatile Applications

Suitable for high-performance and precision-demanding uses, including household appliances (washing machines, air conditioners), electric vehicles, drones, and industrial machinery.

Benefits of Using Stator Winding Machine for BLDC Motor Production

-

Boosted Production Efficiency

- Automated Operation: Rapidly produces large volumes, far outpacing manual winding methods.

- Continuous Workflow: Advanced machines support 24/7 operation to maximize output.

-

Improved Precision

- High Consistency: Ensures uniform coil parameters by accurately controlling turns, arrangement, and tension.

- Precise Positioning: Servo-controlled systems create tightly packed, neatly arranged windings, enhancing motor.

-

Enhanced Quality

- Fewer Defects: Eliminates manual errors like incorrect turns or insulation damage.

- Performance Optimization: Precise windings reduce copper loss, improving efficiency and stability.

-

Cost Efficiency

- Lower Labor Costs: Automation reduces reliance on skilled operators.

- Minimized Waste: Uses materials efficiently, reducing enameled wire waste.

-

Greater Flexibility

- Versatile Designs: Supports various winding types (e.g., concentrated, distributed) to meet diverse requirements.

- Quick Transitions: Program storage enables swift switching between different motor specifications.

-

Support for Complex Winding Techniques

- Special Patterns: Handles intricate designs like wave or honeycomb windings for advanced motor needs.

- Integrated Welding: Some machines include automated welding for seamless winding connections.

-

Reduced Defect Rates

- Minimized Human Error: Mechanized processes avoid issues caused by fatigue or inexperience.

- Stable Tension Control: Ensures evenly distributed wires, preventing short circuits or poor connections.

-

Eco-Friendly Production

- Energy Efficiency: Precision winding enhances motor performance, reducing energy consumption.

- Material Savings: Optimized design minimizes waste.

Why Choose DETZO’s BLDC Motor Stator Winding Machines?

-

Expertise and Innovation

- Technical Excellence: Years of experience in winding machine production, with a focus on BLDC motor innovations.

- Tailored Solutions: Designed for the unique demands of BLDC motors, supporting diverse winding structures.

-

Outstanding Performance

- Speed & Precision: High-precision servo systems ensure rapid, accurate winding with tightly packed coils.

- Reliability: Robust design for extended operation without compromising quality.

-

Cutting-Edge Automation

- Integrated Features: Includes tension control, automated welding, and loading/unloading to reduce manual intervention.

- User-Friendly Interface: Advanced HMI for simple and intuitive operation.

- Program Storage: Enables quick switching between different winding specifications.

-

Quality Assurance

- Consistency: Delivers uniform winding parameters, significantly reducing defects.

- Dependable Tension Systems: Protects against coil damage from uneven tension.

-

Enhanced Efficiency

- High Output: Exceeds traditional winding methods in production speed, ideal for mass manufacturing.

- Minimal Downtime: Easy maintenance ensures continuous operation.

-

Support for Energy-Efficient Motors

- Optimized Performance: Precisely crafted windings improve motor efficiency, meeting energy-saving demands.

- Material Efficiency: Reduces waste, cutting production costs.

-

Trusted Brand Support

- Global Reach: Comprehensive after-sales support, including installation, training, and technical consultation.

- Custom Solutions: Tailored designs to meet unique production specifications.

DETZO: Best Choice of Motor Stator Winding Machine Manufacturers

BLDC Motors, with their high efficiency, low noise, extended lifespan, and precise control, have become a preferred solution across industries. As a cornerstone of modern energy-saving trends, they play a vital role in sustainable development.

Using a motor stator winding machine for BLDC motor production not only enhances efficiency and accuracy but also optimizes motor performance and reduces costs, making it indispensable for high-quality, high-volume manufacturing.

By choosing DETZO’s BLDC motor stator winding machines, you’re investing in state-of-the-art production tools that deliver exceptional results. Whether your goal is production efficiency or superior product performance, DETZO provides the ideal solution, ensuring reliability and excellence in every step. Contact us without hesitation!