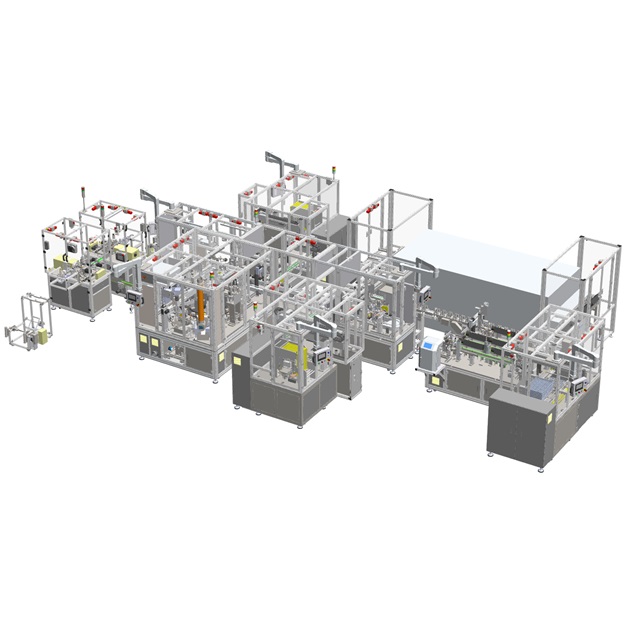

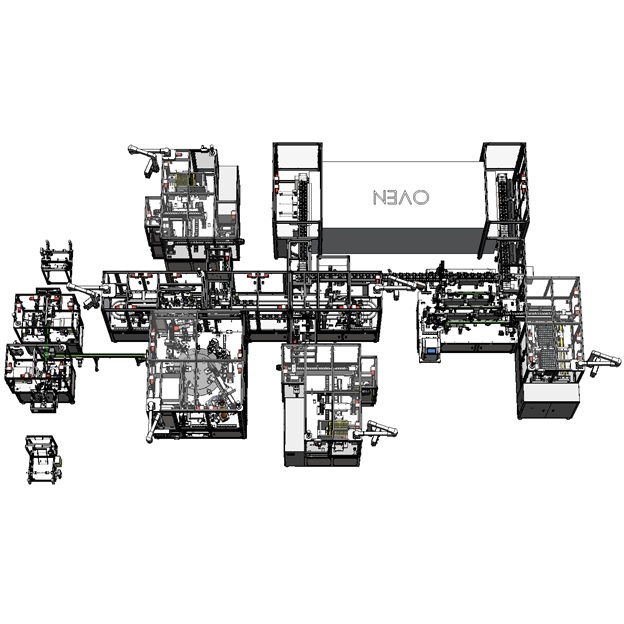

Power Transformer Assembly Production Line

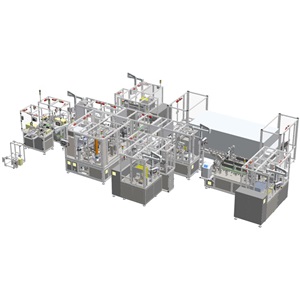

Energy Conversion Transformer: Fully Automated Production Line

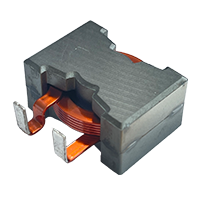

DETZO Fully Automated Energy Conversion Transformer Production Line is specifically engineered for high-performance energy conversion components. It integrates the complete production flow from bare wire to finished products. Through our advanced transformer production line, we ensure every inductor meets the highest industrial standards for energy conversion efficiency and stability.

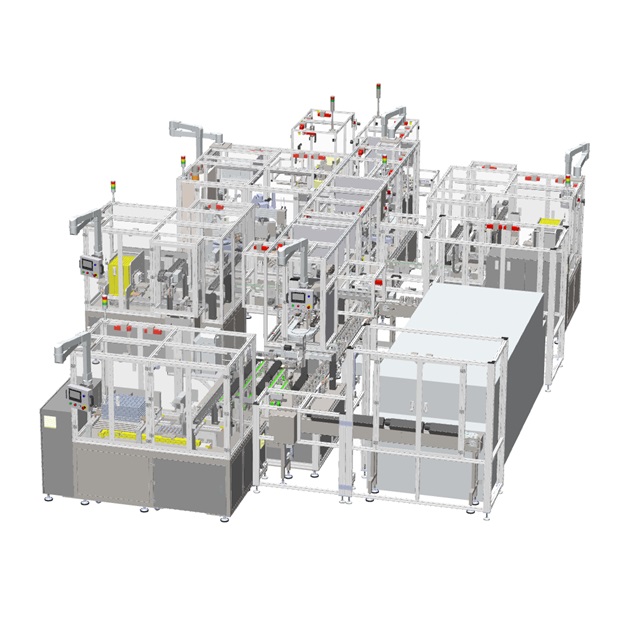

Precision Forming

Integrates flat-wire winding, laser stripping, and bending to build a high-conductivity foundation for energy conversion.

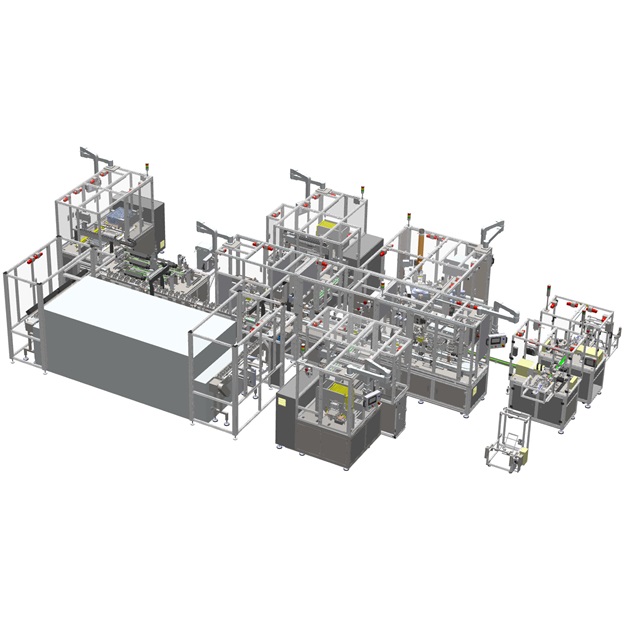

Automated Soldering

Executes dip soldering and core loading to provide reliable electrical connections for energy conversion transformers.

Smart Vision & Assembly

Precise gluing controlled by CCD vision inspection, followed by inline curing to ensure optimal structural integrity.

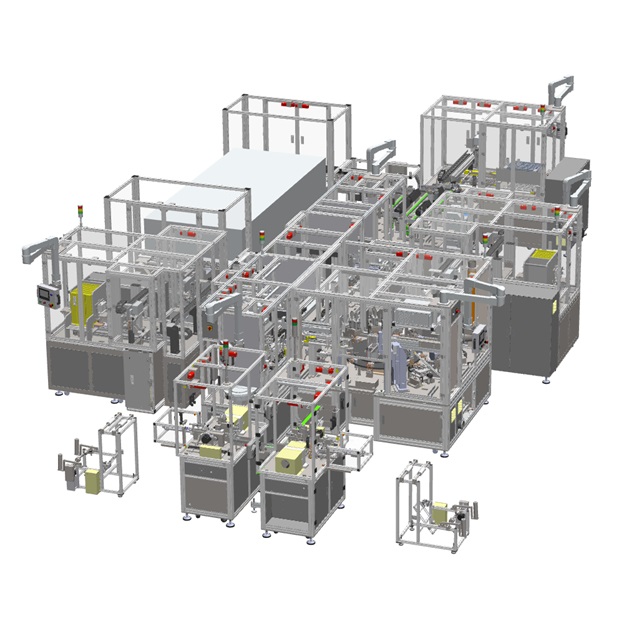

Functional Testing

Synchronous DCR and Inductance measurement to deliver the highest quality energy conversion components.

Optimizing Production Flow, Empowering High-Efficiency Energy Conversion

DETZO Turnkey Solutions

Energy Conversion Transformer: Automated Production Flow

STEP 01 | Precision Winding & Forming

- A. Automatic flat-wire winding machine - High-fill rate technology

- B. Laser wire enamel stripping - Precise insulation removal

- C. Coil leg bending mechanism - Customized terminal forming

STEP 02 | Assembly & Automated Soldering

- D. Dip flux / E. Dip soldering mechanism - Reliable electrical connectivity

- F. Down core / J. Upper core loading - Automated core alignment

STEP 03 | Smart Gluing & Inline Curing

- G. Gluing mechanism / H. CCD vision inspection - Real-time Q'ty & position control

- I. Transportation conveyor / L. Oven & cooling - Efficient inline curing process

STEP 04 | Quality Verification & Collection

- K. Resistance (DCR) / M. Inductance test - Ensuring high energy conversion specs

- N. Complete choke collect machine - Automatic sorting and final collection