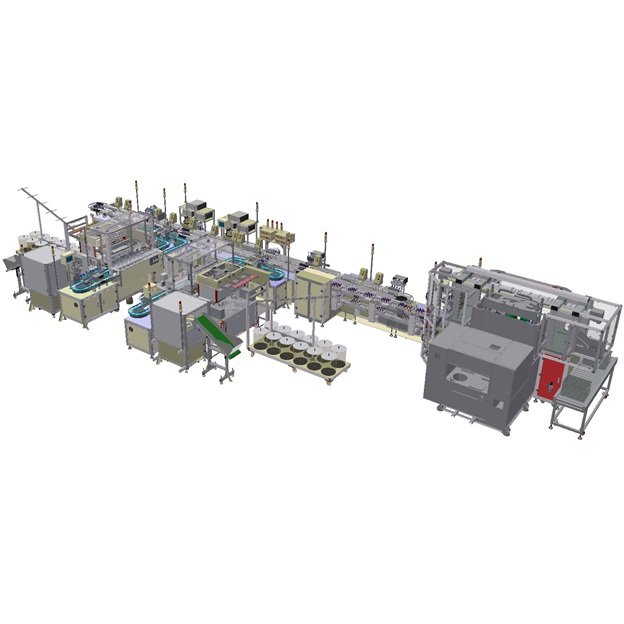

Water Valve Coil Assembly Production Line

Customized model 07

Water Valve Coil: Assembly Production Line

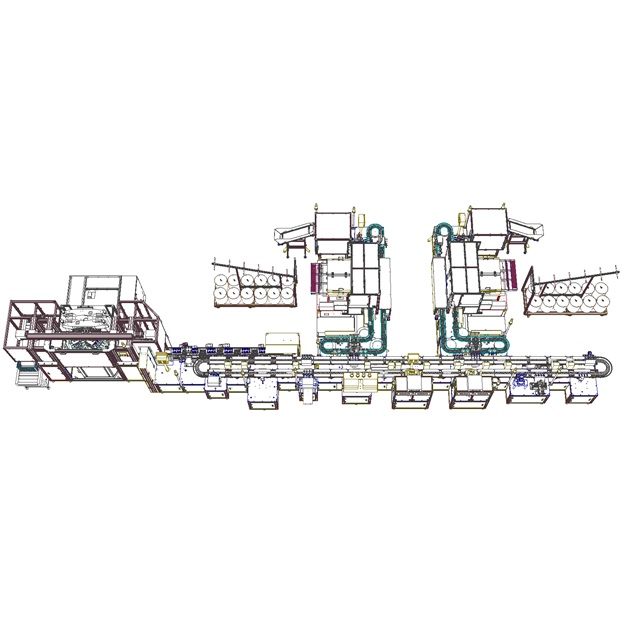

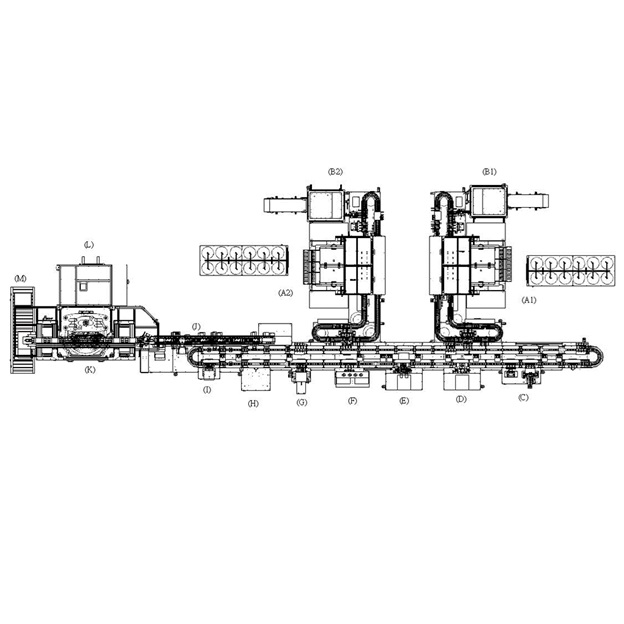

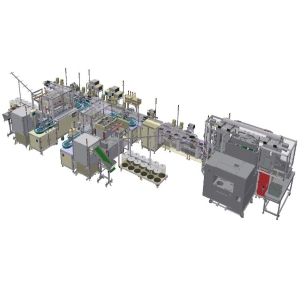

DETZO Water Valve Coil Assembly Production Line is an integrated high-efficiency production line for water valve coils. It combines precision winding, advanced soldering, QC testing, and injection molding into a seamless workflow connected by a specialized conveyor system.

Seamless integration from winding to injection molding

DETZO Turnkey Solutions

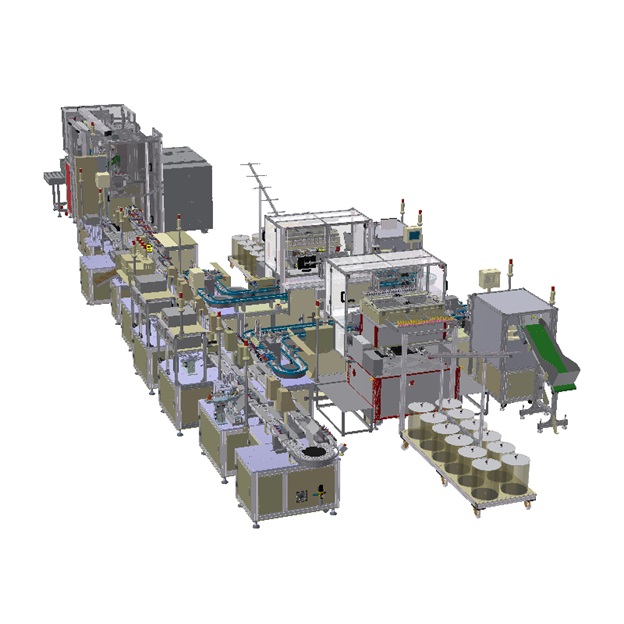

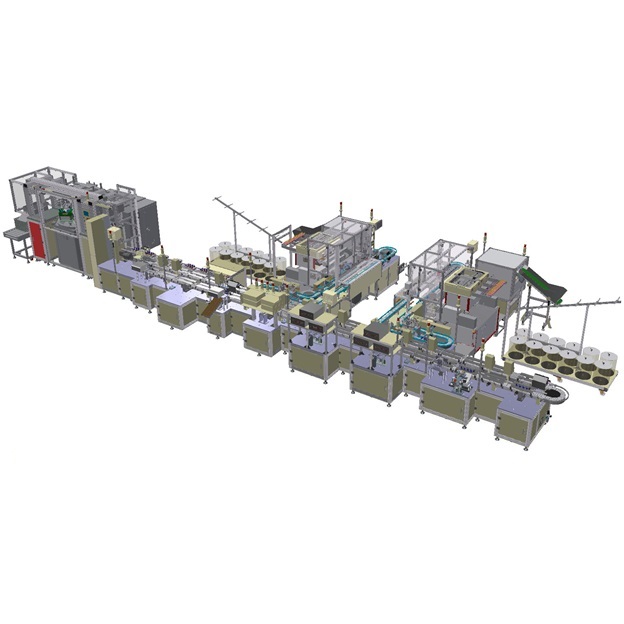

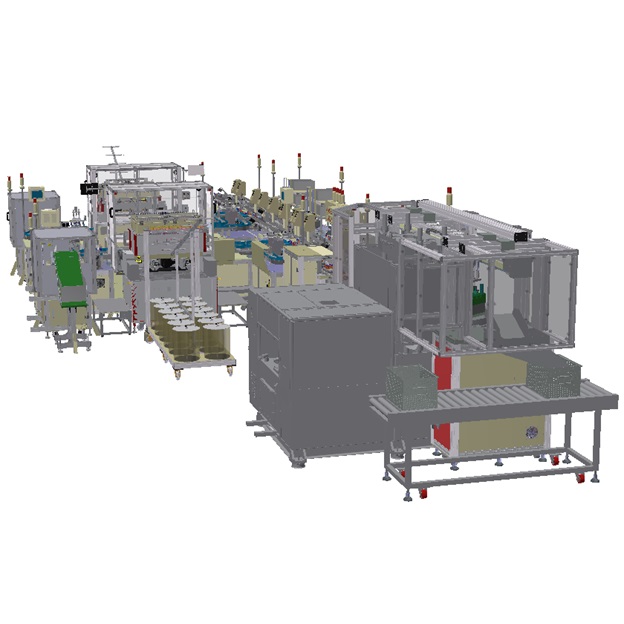

Water Valve Coil: Production Process Flow

STEP 01 | Feeding & Winding System

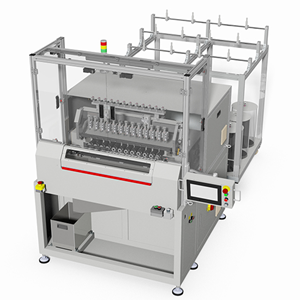

- A1 & A2. DSW-6012PT automatic coil winding machine

- B1 & B2. Vibrating plate automatic bobbin feeding machine

STEP 02 | Soldering & Inspection

- C. Fluxing station - Flux coating pre-treatment

- D. Pin detective station - Pin position verification

- E. High frequency soldering machine No. 1 & 2

- F. High frequency soldering machine No. 3 & 4

- G. Blower cooling station - Fast cooling and joint stabilization

STEP 03 | Testing & Smart Conveying

- H. Resistance testing station - 100% Electrical quality check

- I. NG unloading station - Automated rejection of defective parts

- J. Flexlink conveyor - High-stability process transmission

- K. Servo conveyor mechanism in front of injection machine

STEP 04 | Molding & Final Output

- L. Injection machine - Coil encapsulation molding

- M. Powerless conveyor - Final product output