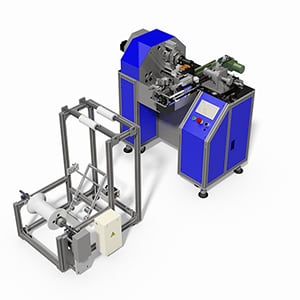

Flat-Wire Winding Machine

Single-Spindle Flat Wire Winding: Precision Solutions for High-Power & EV Electronics

DETZO’s single-spindle flat wire winding machines are specifically designed for large cross-section rectangular wires. By combining high structural rigidity with precision servo control, they fulfill the strict requirements for slot fill factor and thermal efficiency in solar, automotive, and high-power applications.

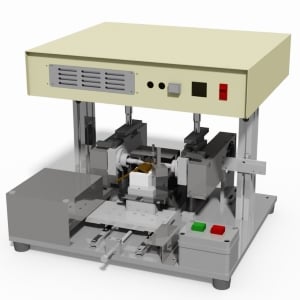

Core Expertise: Precision Winding & Structural Stability

- Heavy-Duty Single-Spindle Rigidity: Engineered with high torque to handle thick flat wires while maintaining superior positioning accuracy and consistent layering.

- Constant Tension & Anti-Twist System: Specialized tensioners and layer compensation systems prevent wire flipping at corners, ensuring a flat and snug winding every time.

- Precision Layering & Tolerance Compensation: High-resolution servo control compensates for wire thickness variations, achieving a higher slot fill factor than traditional round wires.

- Digital Parameter Management: User-friendly HMI allows intuitive setting of pitch and winding speed, significantly reducing setup times for diverse product specs.

Core Application Domains

01. Solar Power Systems

Ideal for: High-efficiency PV inverters and large energy storage inductors.

Value: Maximizes cross-sectional area to minimize skin effect losses, critical for green energy conversion efficiency.

02. Automotive Electronics

Ideal for: EV drivetrain modules, OBCs (On-Board Chargers), and sensing units.

Value: Compact winding structures reduce component volume and enhance mechanical strength for automotive durability standards.

03. High-Power Industrial Coils

Ideal for: High-frequency transformers and high-current filtering inductors.

Value: Precise spindle control ensures superior thermal dissipation and structural integrity, extending lifespan under high-heat conditions.

Process Reliability & Monitoring

Precision is paramount. Our flat wire winding machines feature real-time tension sensing and anomaly detection. Combined with automated unloading systems, we ensure a high-yield production process for high-value components.

We bridge decades of winding expertise with the specific standards of EV and Solar industries, delivering robust torque control and layering technology to solve wire twisting and layering inconsistencies.