Relay

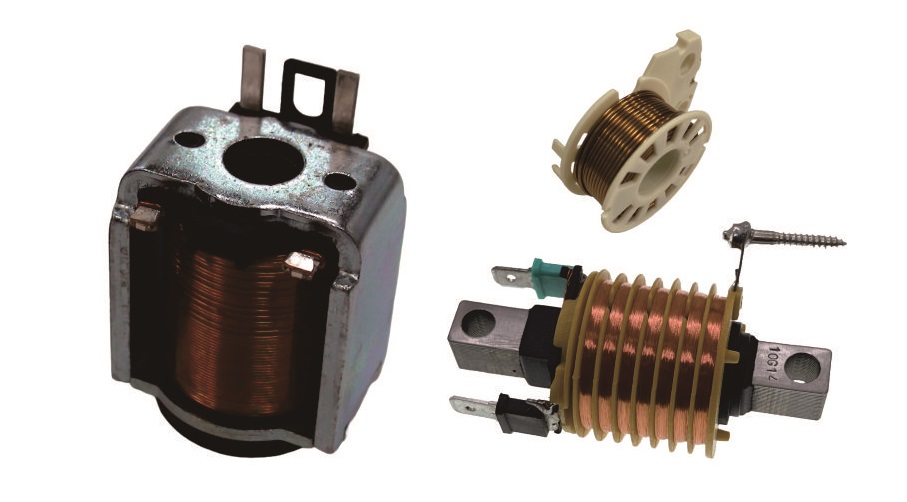

A Relay is a fundamental electronic control component designed to bridge control systems with high-power electrical circuits. Acting as an automated switch that utilizes low-current signals to regulate significantly higher currents, relays provide essential functions such as circuit regulation, safety protection, and seamless signal conversion. The reliability of these switching operations depends heavily on the electromagnetic stability and manufacturing quality of the internal coil.

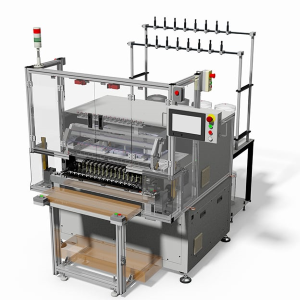

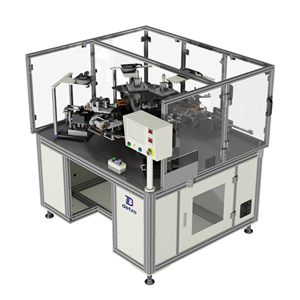

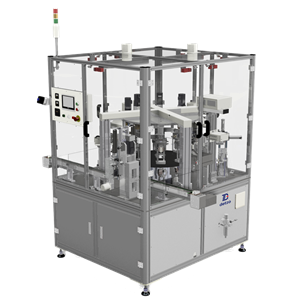

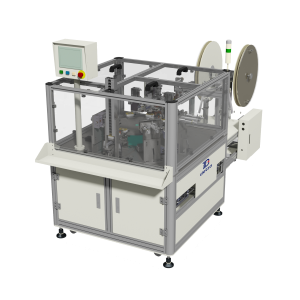

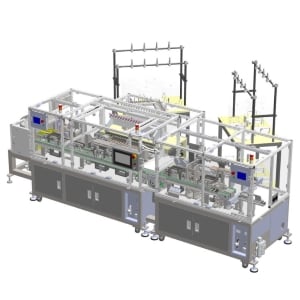

DETZO offers high-performance automated production systems specifically optimized for relay manufacturing, including high-speed Relay Coil Winding Machines and precision DIP Soldering Systems. We provide end-to-end solutions to ensure superior electrical contact and production efficiency. For any inquiries regarding relay winding and assembly technology, please feel free to Contact DETZO.

Imagine using a tiny remote control to open a massive dam gate—that is the essence of a Relay. It allows a delicate "brain" (like a computer chip) to control a powerful "muscle" (like an industrial motor) without direct physical connection, ensuring both safety and precision.

The "Snap" of Precision: When current flows through the internal coil, it creates a magnetic pull that snaps the electrical contacts together. If the winding is uneven, this pull becomes jittery, causing tiny sparks called "Arcing" that eventually burn out the device.

Energy Efficiency: A high-quality relay shouldn't waste energy as heat. Precision winding ensures the magnetic field is concentrated exactly where it's needed, allowing the relay to stay cool and reliable even during years of continuous operation.

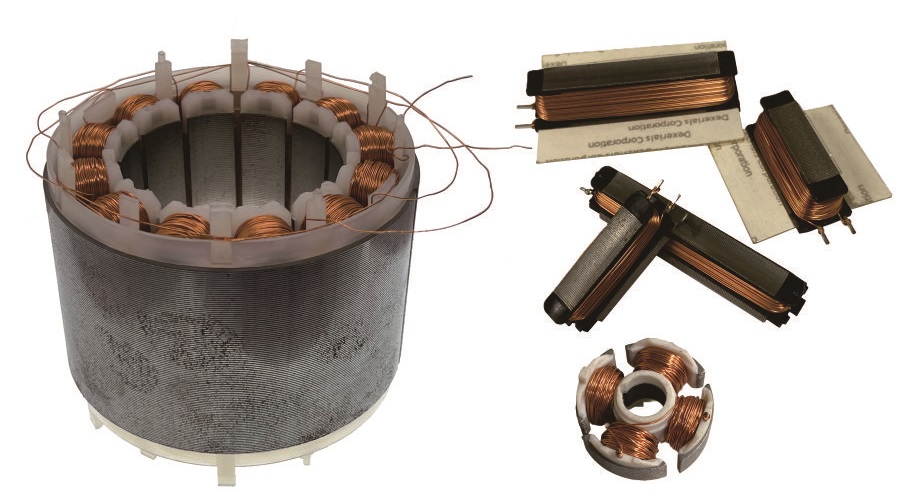

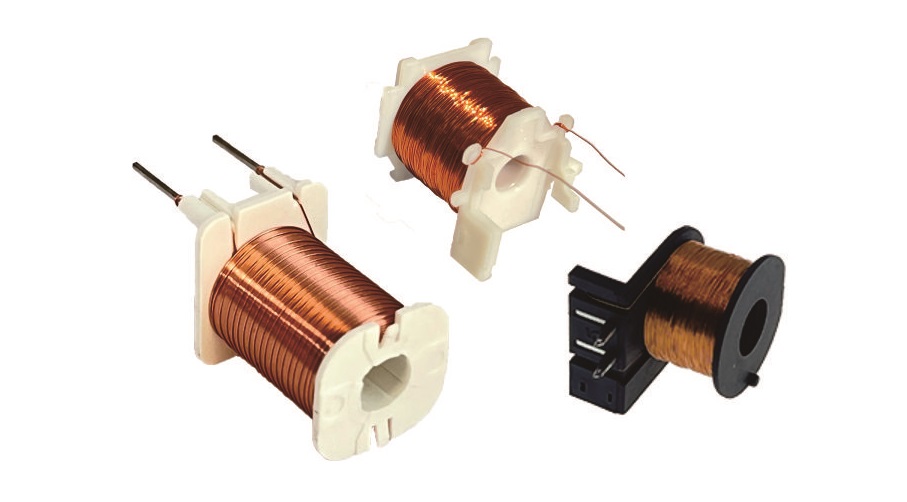

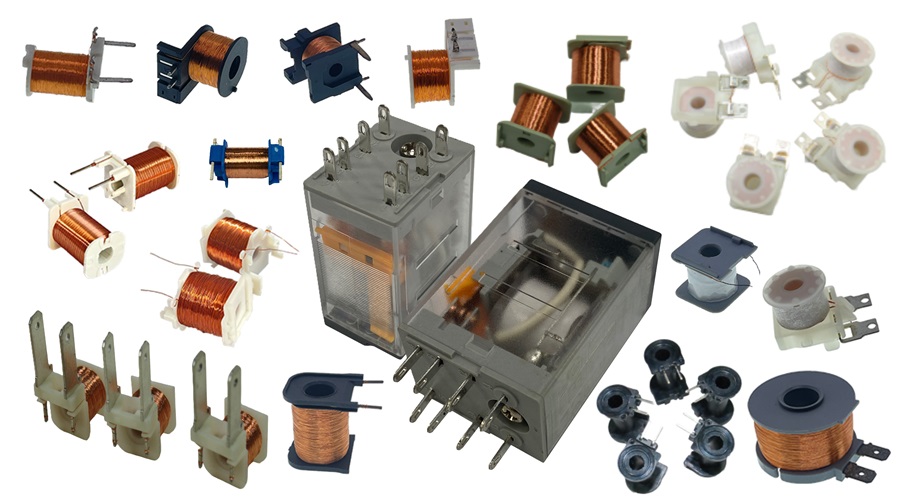

Relays come in various forms, each designed to handle different voltage levels and environmental stresses. Understanding these categories is key to selecting the right production technology:

01. Signal Relays

Style: Typically ultra-miniature, low-profile SMT or DIP packages used on Printed Circuit Boards (PCB).

Use Case: Designed to switch low-current signals (under 2A) with extremely low distortion. These are the "nervous system" of telecommunications, routers, and high-end audio equipment.

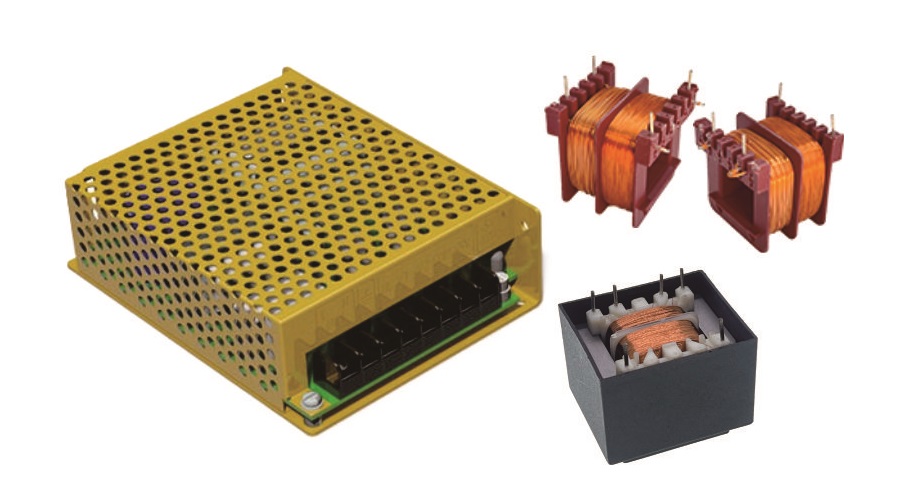

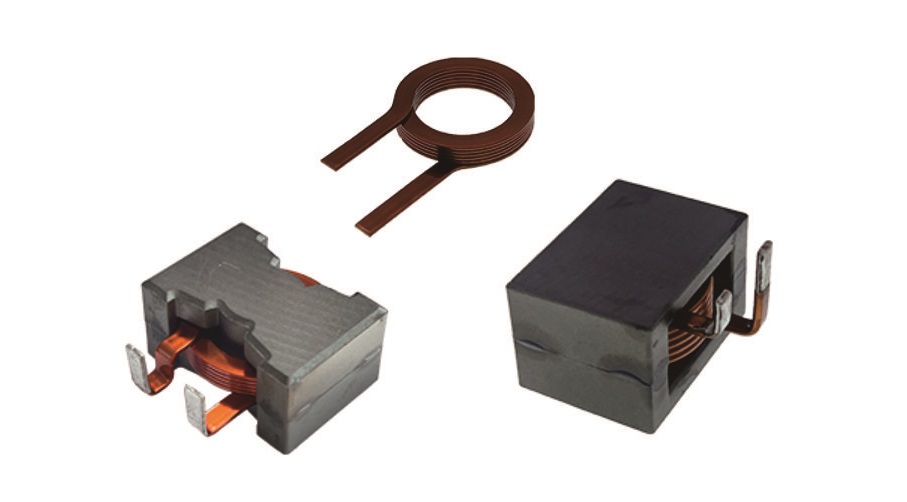

02. General Purpose / Power Relays

Style: Often seen in "Ice Cube" style transparent plastic housings with 5, 8, or 14 pins, designed for socket mounting or PCB.

Use Case: These are the workhorses of home appliances (fridges, air conditioners) and industrial control panels. They handle currents from 10A to 30A.

03. EV Contactors / High-Voltage Relays

Style: Large, heavy-duty hermetically sealed cylindrical or rectangular units with thick copper terminals.

Use Case: Critical for Electric Vehicles (EV) and Renewable Energy storage. They safely connect and disconnect high-voltage batteries (400V-800V).

04. Latching Relays

Style: Similar to power relays but features a permanent magnet inside to maintain position without continuous power.

Use Case: Widely used in smart meters and lighting control systems for energy saving. Winding quality is critical to ensure the "pulse" is strong enough to switch positions.

05. Reed Relays

Style: Thin glass tubes containing metallic reeds, surrounded by a copper coil.

Use Case: Perfect for high-speed switching in automated test equipment (ATE) and medical sensors due to their incredibly fast response times.

As we move toward Electric Vehicles (EV) and Smart Grids, the requirements for relays are shifting towards:

High Voltage & Current

Handling higher power loads in compact spaces, especially for EV battery management and charging stations.

Long-Life Reliability

Developing durable coils that can withstand millions of switching cycles without failure.

Miniaturization

Reducing the footprint of relays for smart home devices while maintaining high output performance.

Ultra-Stable Layer Winding:

Our equipment provides precise wire layering, which prevents overlapping and ensures a uniform magnetic field for every relay produced.

High-Speed Fine Wire Handling:

Many relays use wires thinner than a hair; our tension control systems ensure high-speed production without wire breakage.

Integrated Pin Wrapping & Soldering:

We combine winding and pin-wrapping into one automated process, ensuring rock-solid, low-resistance connections.

100% Data Traceability:

Track every batch’s tension and resistance data to meet the high-quality standards of the automotive and industrial sectors.

From signal relays to high-power EV contactors, DETZO helps you achieve higher yields and better quality. Let’s work together to drive the future of electrical control. Please feel free to Contact DETZO.