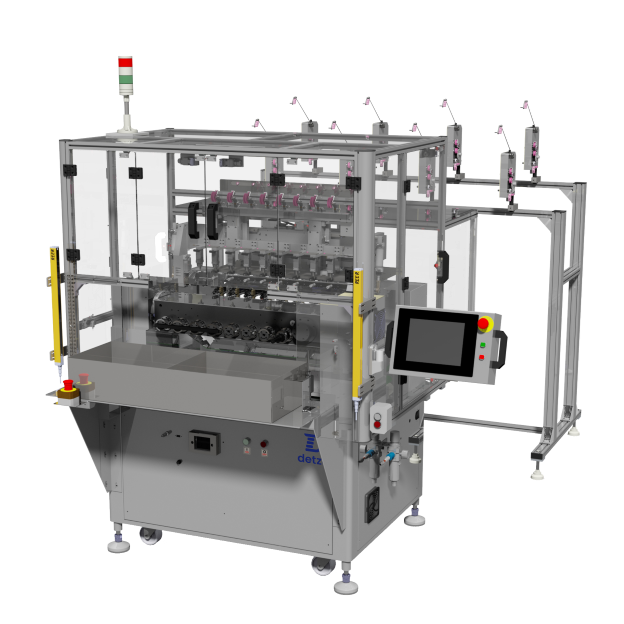

Automatic Horn Coil Winding Machine

DETZO provides comprehensive coil production solutions tailored for power electronics and automotive component industries. Our machines are engineered for the high-precision winding of transformers, relays, adapters, and switching coils, ensuring superior consistency for inductors, inverters, and primary coils. Additionally, we have a proven track record in the automotive sector, delivering reliable winding for ignition coils, car horns, valve coils, side-mirror coils, and other critical automotive electronics.

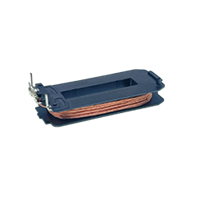

Suitable for - coil winding with outer diameter less than 60mm

DSW-8008D is a flip-type horn coil winding machine that has 8 spindles and three built-in needle winding angle settings of 0°, 90°, and 120° can complete winding at multiple angles at one time and uses the Keyence system combined with the AC servo motor drive system for precise positioning to achieve multiple tasks. It provides a 10-inch HMI conversational editing program, through programming, coils of different sizes and shapes can be wound. In addition, it is equipped with an automatic winding pin and a residual wire removal system, which can cut the wire after the winding is completed.

DSW-8008D can used for variously-shaped bobbin winding with outer diameters less than 60mm, such as the car horn coil that is a crucial component of the car horn, responsible for converting electrical energy into sound energy, and emitting clear and loud warning signals. It is typically made up of wire wound into a coil, working with a magnet to produce vibrations, enabling sound amplification and dispersion, thus serving as a vital device for ensuring driving safety.

| Nozzle Movement | X: 120 / Y: 160 / Z: 80 mm | Positioning Accuracy | Disp: 0.01mm / Angle: ±0.5° |

|---|---|---|---|

| Winding Range | Max. Dia: 60mm / Max. Width: 90mm | Wrapping Angle | 0°, 90°, 120° |

| Infrastructure | 3Φ 220Vac | 50~60Hz | 0.4~0.6Mpa | Power Consumption | 5.5KW |

| Storage Method | Memory Card | Machine Weight | 1200kg ±10 |

| Machine Dimensions | 1700(L) x 1400(W) x 1900(H) mm | ||

| Stripping Spec (Opt.) | Stripping Wire Range: Ø0.20 ~ Ø1.20 mm | ||