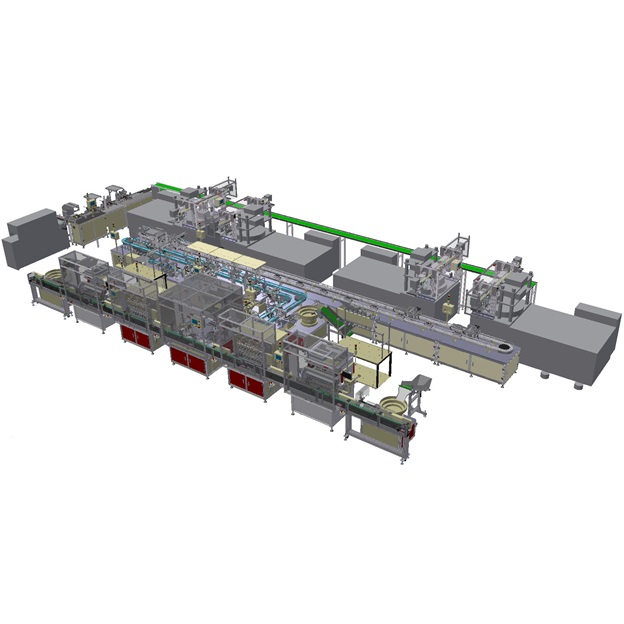

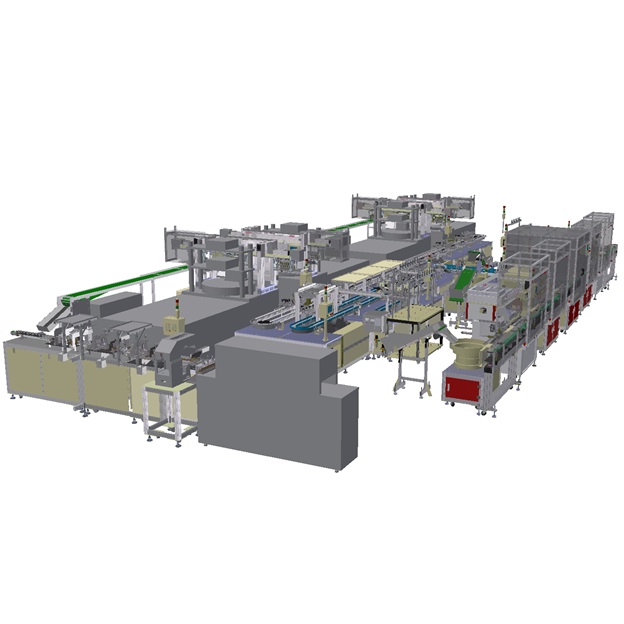

Solenoid Valve Coil Assembly Production Line

Solenoid Valve Coil Assembly Line

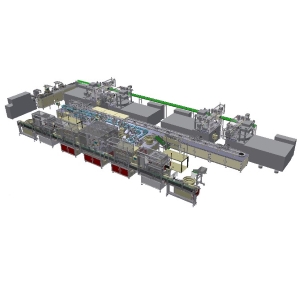

The DETZO Automated Production Solution features high-performance synchronized processes, integrating precision winding, automated taping, and advanced injection molding.

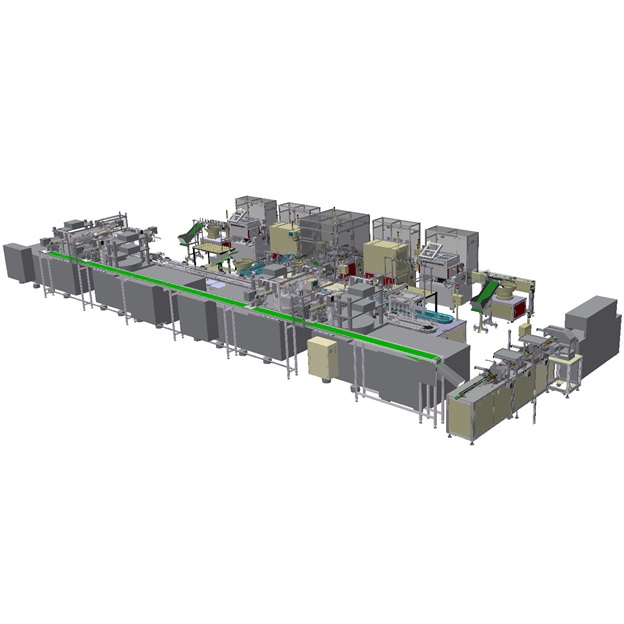

Automated Winding & Taping

Vibratory Bowl Bobbin Feeders provide precise supply to DSW-4216PT Automatic Winding Machines and DSW-TP8008 Automatic Taping Machines for efficient multi-axis insulation.

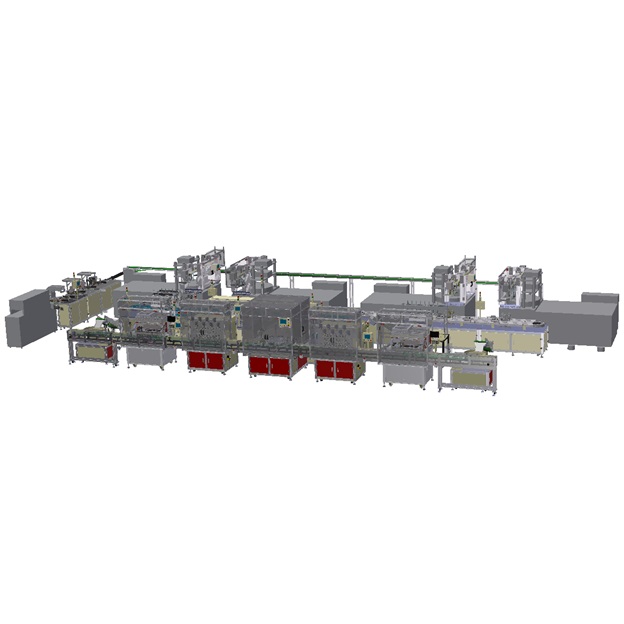

Soldering & Assembly Logistics

The Servo Conveyor System ensures stable synchronization, while the 8-Station Soldering Machine and Semi-finished product assembly line perform high-speed integration.

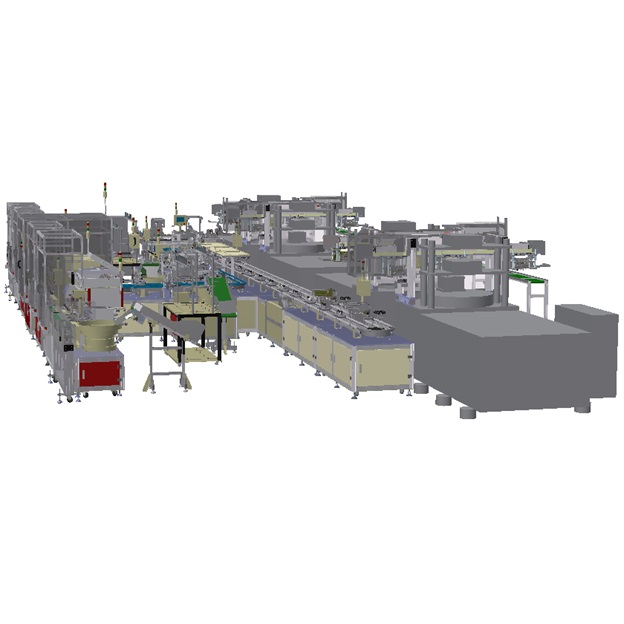

Injection Molding & Robotics

Components flow into the Injection Molding Machines + Robotic Arms via the buffer system for automated loading and precision molding, followed by the Finished Product Conveyor.

Finishing & Quality Inspection

Involves manual removal of plastic burrs and placement on test conveyors, finishing molded parts to meet rigorous quality standards before the testing phase.

Full-Process Integration from Winding to Injection Molding

DETZO Turnkey Solutions

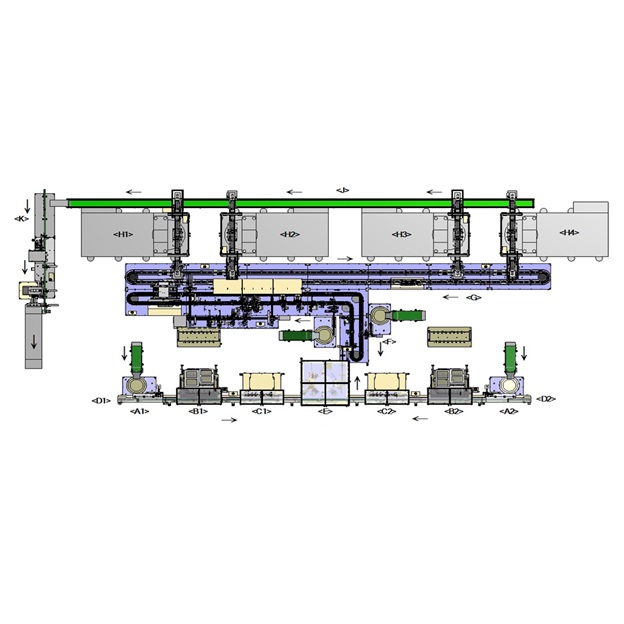

Solenoid Valve Coil Assembly Line | Production Timeline

STEP 01 | Automated Winding & Taping

- A1/A2. Vibratory Bowl Bobbin Feeder - Automated part orientation and supply

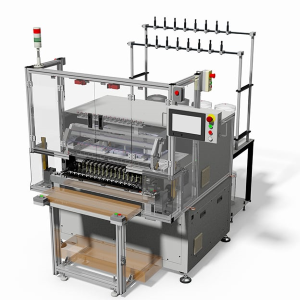

- B1/B2. DSW-4216PT Automatic Winding Machine - High-precision multi-axis winding

- C1/C2. DSW-TP8008 Automatic Taping Machine - Automated insulation wrapping process

STEP 02 | Soldering & Assembly Logistics

- D1/D2. Servo Conveyor System - Stable material flow and precise synchronization

- E. 8-Station Soldering Machine - Multi-station rotary soldering for high output

- F. Semi-finished product assembly line - Automated component integration and assembly

STEP 03 | Injection Molding & Robotics

- G. Semi-finished product to inject plastic line - Buffer system for molding preparation

- H1~H4. Injection Molding Machine + Robotic Arm - Automated loading and precision molding

- J. Finished Product Conveyor - Collection and transport of molded components

STEP 04 | Finishing & Quality Inspection

- K. Manual removal of plastic burrs / Place on test conveyor - Precision finishing and transfer to testing phase