CNC Automatic Coil Winding Machine

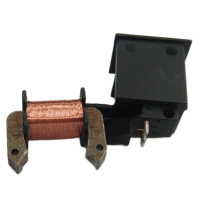

The DETZO DSW-8004PC Series is a high-performance winding system specifically engineered for coils with an outer diameter under 60mm. Featuring precise servo control and a robust architecture, this series delivers high-efficiency production for transformer, relay, inductor, and switching coils. For power systems and the automotive market, the DSW-8004PC demonstrates exceptional durability in manufacturing starting coils, stepper motor coils, and automotive coils. Whether for ignition, car horn, valve, side-mirror, inverter, or adapter coils, it provides consistent winding precision and yield, serving as the premier automated choice for diverse related small-to-medium-sized coil production.

Suitable for - coil winding with outer diameter less than 60mm

Winding + Heating + Stripping

Winding + Stripping

Produced using DSW-8004V

Advanced Control

PLC 4-axis CNC technology ensures precise and consistent winding. Keyence systems combined with AC servo motors achieve extreme positioning accuracy.

Intuitive Operation

A 10" HMI with conversational programming makes it accessible for beginners. Multi-level management and password protection prevent unauthorized modifications.

High Productivity

Features auto loading/unloading (on select models) and 120-program storage. Unique fixture designs allow for rapid changeovers to maximize output.

Versatile Functions

Built-in 0°, 90°, and 120° settings complete multi-angle wrapping in a single cycle. Simple construction ensures easy control and low maintenance.

DETZO winding machines are widely used in electronics, automotive, and aerospace industries. If you are looking for a powerful, easy-to-operate, and reliable winding solution, DETZO is your best choice.

| Travel of Nozzle | X: 110 / Y: 160 / Z: 80 mm | Positioning Accuracy | Travel: 0.01mm / Angle: ±0.5° |

|---|---|---|---|

| Winding Range | Max. O.D: 60mm / Max. Width: 60mm | Pin Wrapping Angle | 0°, 90°, 120° |

| Power & Air | 3Φ 220Vac | 50~60Hz | 0.4~0.6Mpa | Power Consumption | 4.5KW |

| Data Storage | Memory Card | Machine Weight | 700kg ±10 |

| Dimensions | 1200(L) x 900(W) x 1700(H) mm | ||

| Twisting Spec (Opt.) | Wire Dia: Ø0.03~0.15mm / Length: 300mm | Twisting Performance | Turns: 1~1000T / Speed: 6,000rpm |

| Stripping Spec (Opt.) | Wire Diameter Range: Ø0.20 ~ Ø1.20mm | ||

-624x624.png)