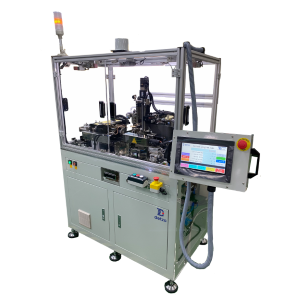

Air-Coil Automatic Winding Machine

The DETZO DSW-4208HFC is a premier winding solution developed for high-quality automotive inductors and hot-air self-bonding coils. At its core, this system integrates a real-time hot-air curing system that synchronizes wire heating during the winding process, ensuring immediate structural integrity and rigid geometric shapes upon de-molding. This technology serves as an eco-friendly and high-efficiency alternative to traditional varnishing processes. Specifically engineered for precision air-core coils, sensor coils, and various automotive self-bonding components, the DSW-4208HFC combines multi-axis synchronized control with an accurate temperature compensation system to perfectly meet the rigorous standards for geometric precision and long-term durability in the automotive industry.

| Wire Type | Self-bonding (Hot Air) | Positioning Accuracy | Linear: 0.01mm / Angular: ±0.5° |

|---|---|---|---|

| Travel Distance | X: 110 / Y: 100 / Z: 80 mm | Winding Range | Max Coil Ø: 30mm / Max Width: 10mm |

| Facility Req. | 1Φ 220Vac | 50~60Hz | 0.4~0.6Mpa | Power Consumption | 10 KW |

| Storage | Memory Card | Machine Weight | 850 kg ±10 |

| Dimensions | 1200(L) x 860(W) x 1700(H) mm | ||