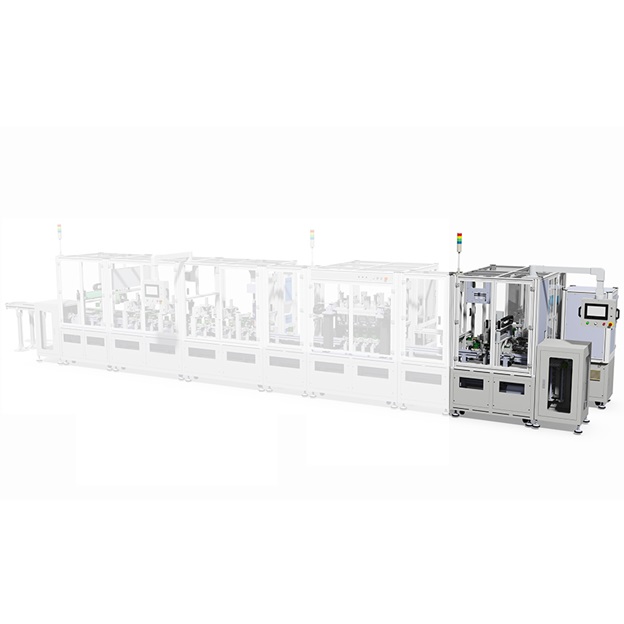

Automated Brake Coil Production Line

Brake Coil: Fully Automated Production Line

The DETZO Automated Brake Coil Production Line is designed for high-performance industrial components, integrating a complete process from bobbin feeding to precision pinning, winding, and testing. Our advanced transformer production line configuration ensures every coil meets the highest standards for electrical performance and structural stability.

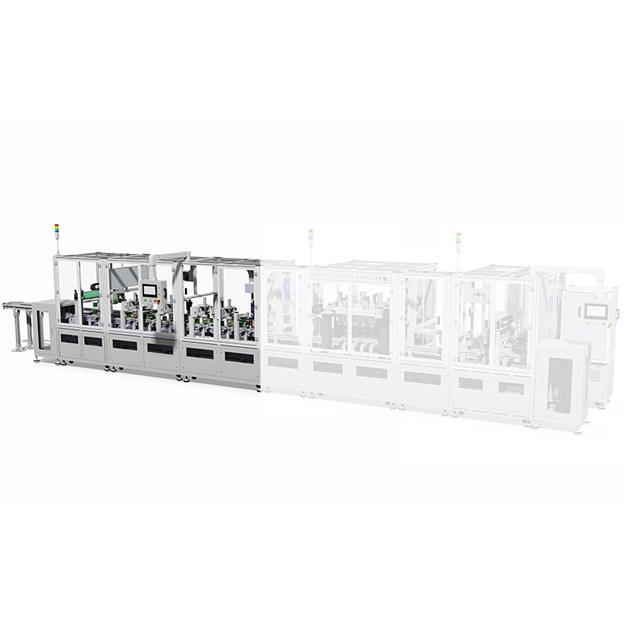

Automatic Feeding

Utilizing a vibrating plate automatic bobbin feeding machine for precise component orientation.

Precision Pinning

The pin inserting machine executes high-accuracy terminal placement for structural integrity.

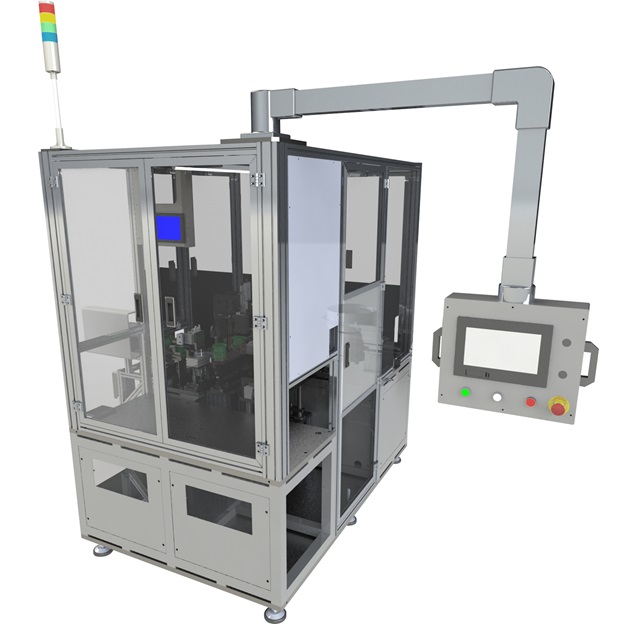

Vertical Winding

Equipped with the DSW-15004V vertical winding machine for precision layering and tension control.

Automated Welding

Integrated spot welding machine for reliable electrical joining and enhanced durability.

Resistance Testing

Automated resistance testing ensures superior quality control and screenings.

Output & Connecting

Finished product output for seamless connection with back-end manufacturing processes.

Optimizing processes for high-quality industrial coils

DETZO Turnkey Solutions

Brake Coil: Production Process Flow

STEP 01 | Feeding & Pin Insertion

- A. Vibrating plate automatic bobbin feeding machine - Precision component orientation

- B. Pin inserting machine - High-accuracy terminal placement

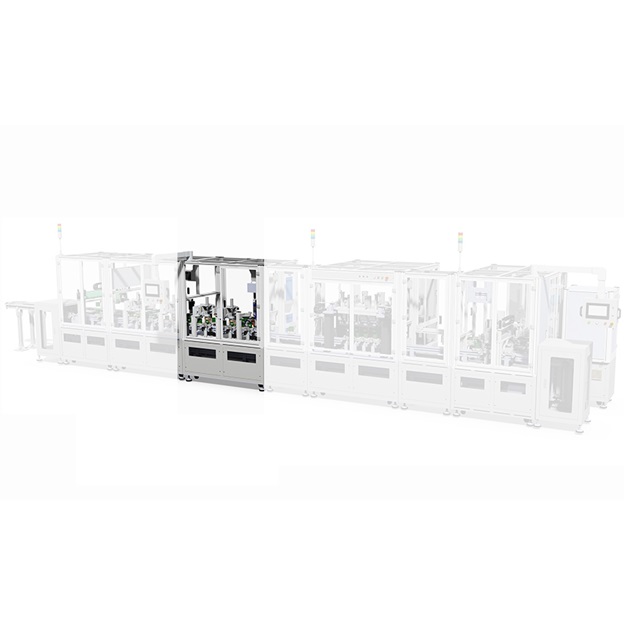

STEP 02 | Vertical Winding Process

- C. DSW-15004V vertical automatic coil winding machine - Specialized winding technology

STEP 03 | Welding & Quality Testing

- D. Spot welding machine - Reliable electrical joining

- E. Resistance testing machine - Automated electrical quality screening

STEP 04 | Output & Collection

- F. Finished product output - Automated collection for back-end connection