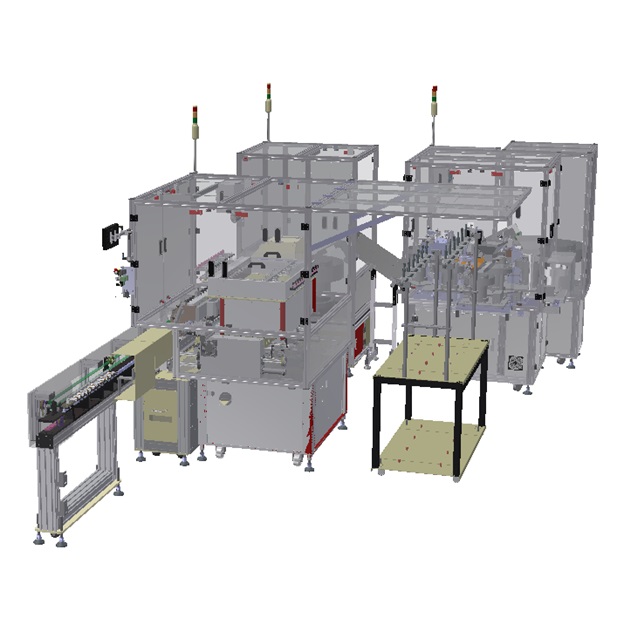

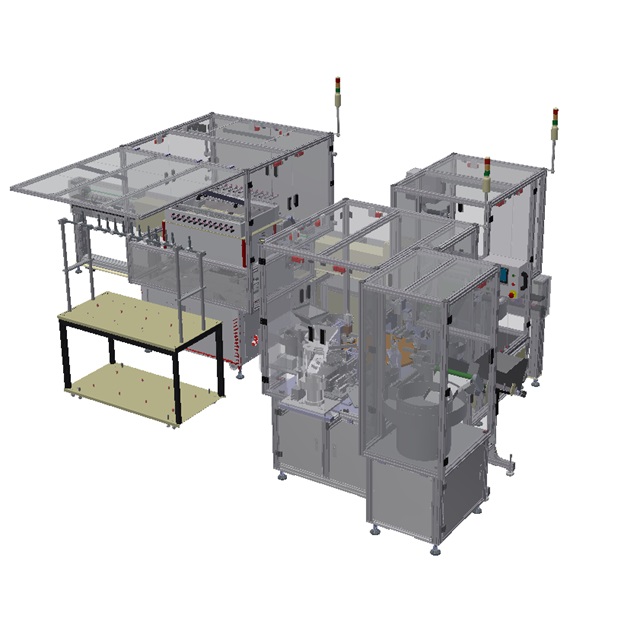

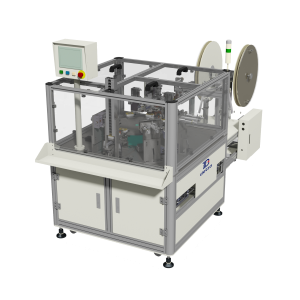

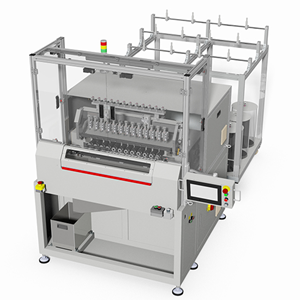

Solenoid Valve Coil Production Line

Customized model 08

Solenoid Valve Coil: Automatic Production Line

The DETZO Solenoid Valve Coil Production Line system is specifically designed for solenoid valve coils, integrating precision pin insertion with high-efficiency automatic winding. This solenoid coil production line maximizes consistency and throughput through a fully automated workflow.

Integrated pin insertion and winding solutions for superior efficiency

DETZO Turnkey Solutions

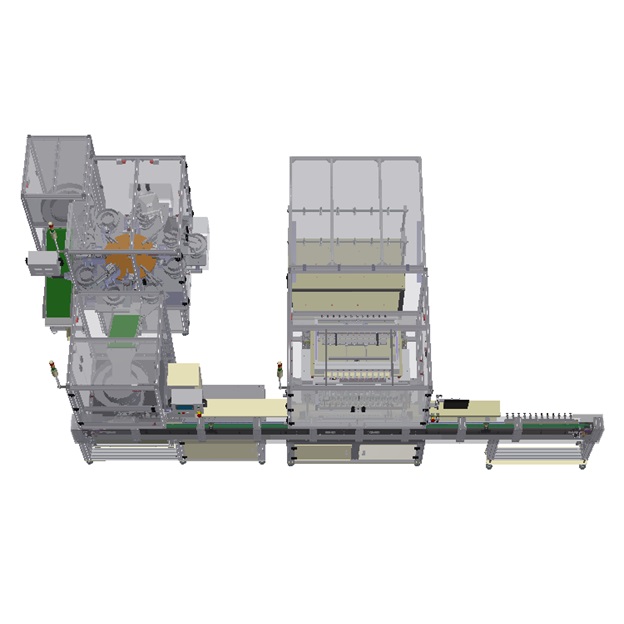

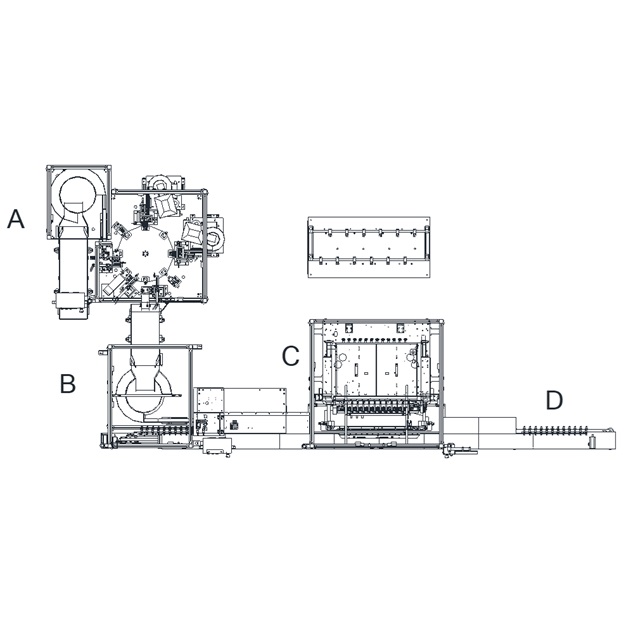

Solenoid Valve Coil: Production Process Flow

STEP 01 | Feeding & Pin Insertion

- A. Automatic rotary pin inserting machine - High-precision terminal placement

- B. Vibrating plate automatic bobbin feeding machine - Continuous automated supply

STEP 02 | Precision Winding

- C. DSW-6012PTN automatic coil winding machine - Multi-axis winding with stable tension control

STEP 03 | Finished Product Output

- D. Finished product output - Seamless integration for downstream processing