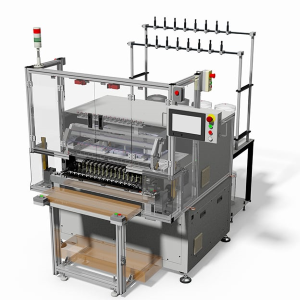

Fully Automatic Transformer Coil Winding Machine

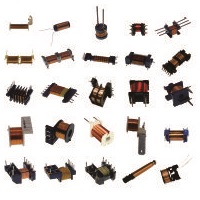

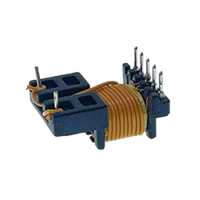

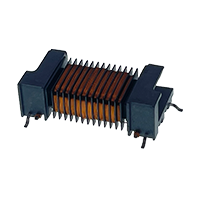

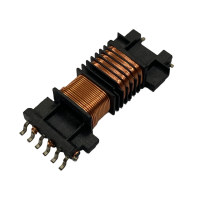

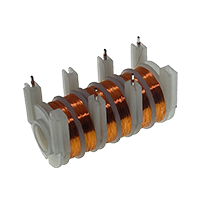

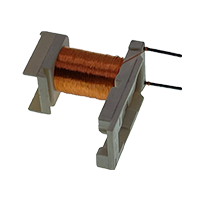

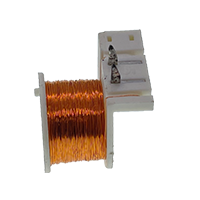

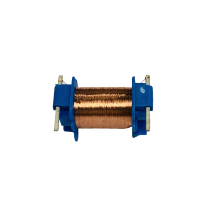

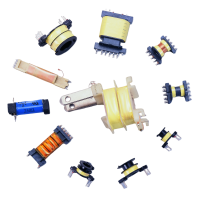

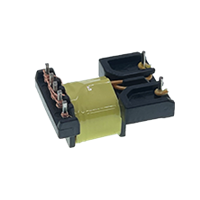

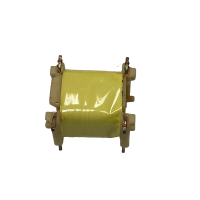

The DETZO DSW-4208 Series is engineered for high-precision micro-coil winding. With superior motion accuracy, it is the ideal solution for miniature transformer, relay, inductor, and switching coils. For intricate adapter and primary coils, the DSW-4208 delivers exceptional stability. It is also extensively utilized for automotive side-mirror, valve, horn, and ignition coils, representing the ultimate choice for fine-wire processing and ultra-precise quality.

Suitable for - coil winding with O.D. less than 30mm

Tin wire winding

TEX-E winding

Copper wire winding

Suitable for–Winding and Taping

DSW-4208PC fully automatic winding machine combines the Keyence platform with an AC servo motor drive system ensuring that your winding tasks are executed with the utmost accuracy, meeting even the most demanding specifications and this fully automatic transformer winding machine features an automatic pin wrapping and residual wire removal system. This ensures that winding is precise, and any leftover wire is efficiently removed, maintaining the quality and integrity of your products.

DSW-4208PC fully automatic winding machine is designed to streamline your winding operations and optimize productivity it offers a host of features that cater to precision, efficiency, and user-friendliness and the machine's straightforward structure, easy-to-use controls, and convenient maintenance procedures contribute to reduced downtime and ensure long-term reliability, the fully automatic winding machine is the ideal solution for businesses seeking winding machine.

- Our transformer coil winding machine is equipped with specialized quick-change winding tooling and an automatic loading and unloading function (excluding special models), this automation reduces manual intervention, allowing you to swiftly adapt to different winding requirements and minimizing setup time and keeping your production processes agile significantly enhancing your production capacity. Besides, built-in nozzle angle settings of 0°, 90°, and 120° allow for the one-time completion of winding tasks at multiple angles. This versatility simplifies the winding process and further accelerates production.

- This automatic transformer winding machine can store up to 120 sets of programs, and effortlessly switch between them as needed high flexibility enables quick adaptation to varying production demands and product specifications. 10-inch Human Machine Interface (HMI) with user-friendly which allows for intuitive program editing in dialogue mode interface simplifies the programming process and makes it accessible to operators of varying skill levels. Besides also have hierarchical management and a password storage function add an extra layer of security to your operations. Unauthorized personnel are prevented from modifying programs, ensuring data integrity and process reliability.

| Nozzle Movement | X: 110 / Y: 100 / Z: 80 mm | Positioning Accuracy | Disp.: 0.01mm / Angle: ±0.5° |

|---|---|---|---|

| Winding Range | Max. Dia.: 30mm / Max. Width: 60mm | Wrapping Angle | 0°, 90°, 120° |

| Infrastructure | 1Φ 220Vac | 50~60Hz | 0.4~0.6Mpa | Power Consumption | 2.5KW |

| Storage Method | Memory Card | Machine Weight | 700kg ±10 |

| Machine Dimensions | 1200(L) x 900(W) x 1700(H) mm | ||

| Twisting Spec (Opt.) | Wire Dia.: Ø0.03~0.15mm / Length: 300mm | Twisting Performance | Turns: 1~9T / Speed: 6,000rpm |

| Taping Spec (Opt.) | Outer Dia.: Ø50~130mm / Width: 2~10mm (Please contact us if it exceeds the usage range) | ||

| Model | DSW-4208PC | DSW-4208PTC | DSW-4208TPC | DSW-4208TPS | DSW-4208HFC |

|---|---|---|---|---|---|

| Automatic 8 Spindles Coil Winding Machine | Automatic 8 Spindles Coil Winding Machine + Twisting Mechanism | Automatic 8 Spindles Coil Winding Machine + Taping Mechanism | Automatic 8 Spindles Coil Winding Machine + Twisting Mechanism + Taping Mechanism | Automatic 8 Spindles Coil Winding Machine + Heater blower Mechanism(Suitable for air core coils) |