Application of BLDC Motor Winding Machine

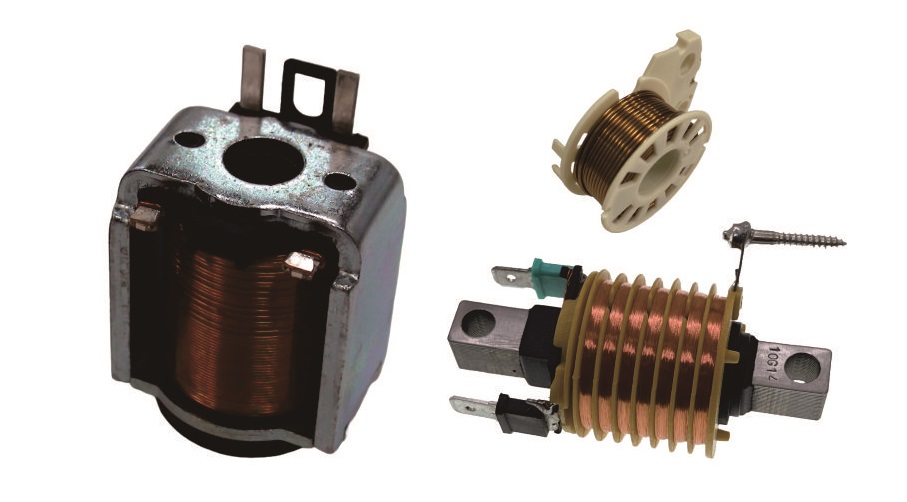

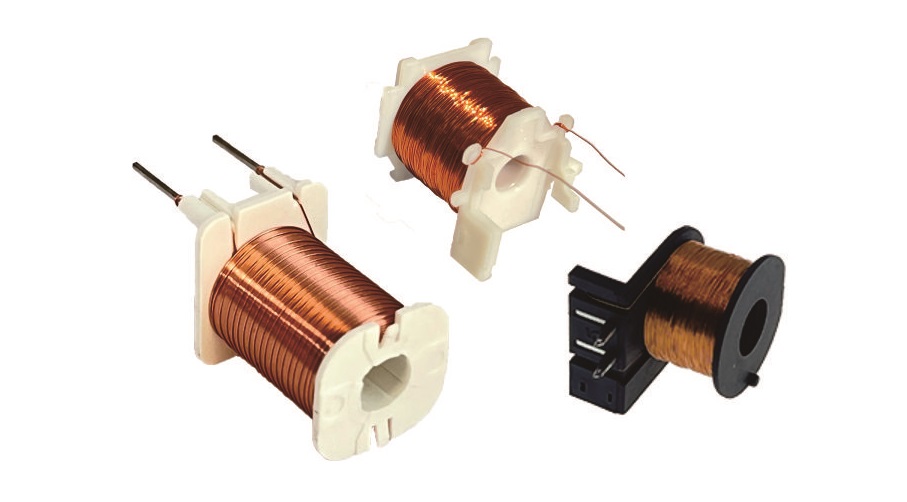

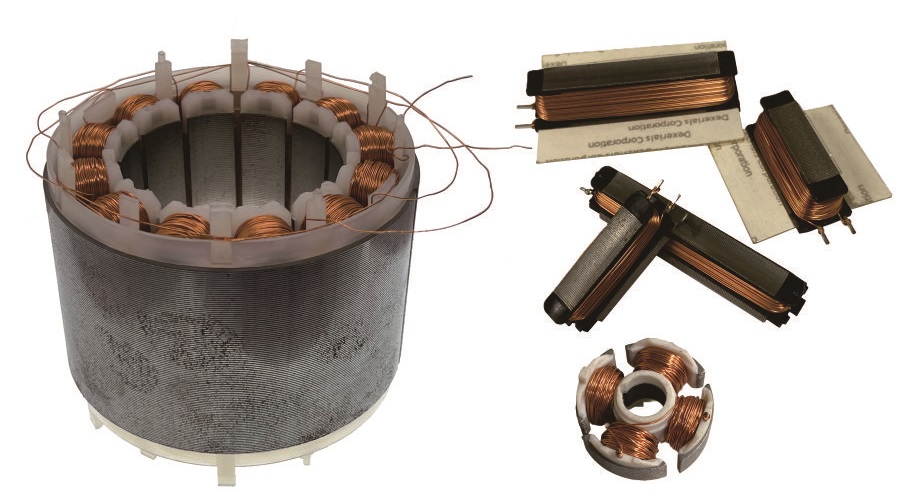

DETZO's BLDC motor winding machines can produce Brushless DC motor(BLDC motor), which has two types: inner rotor and outer rotor. It is an electric motor without brushes and a commutator. The stator current is adjusted to produce torque based on the position of the rotor's permanent magnets. Although it is called a "DC" motor, it is a permanent magnet synchronous motor (PMSM) that uses three-phase electricity. It is called a "brushless DC motor" because it can replace brushed DC motors in many applications. Therefore, BLDC motors are also called EC (electronically commutated) motors to distinguish them from mechanically commutated motors that contain brushes.

If you have any related brushless DC motor coil winding needs, welcome to contact DETZO.

Mastering the BLDC Motor Core: Precision Stator Winding Process

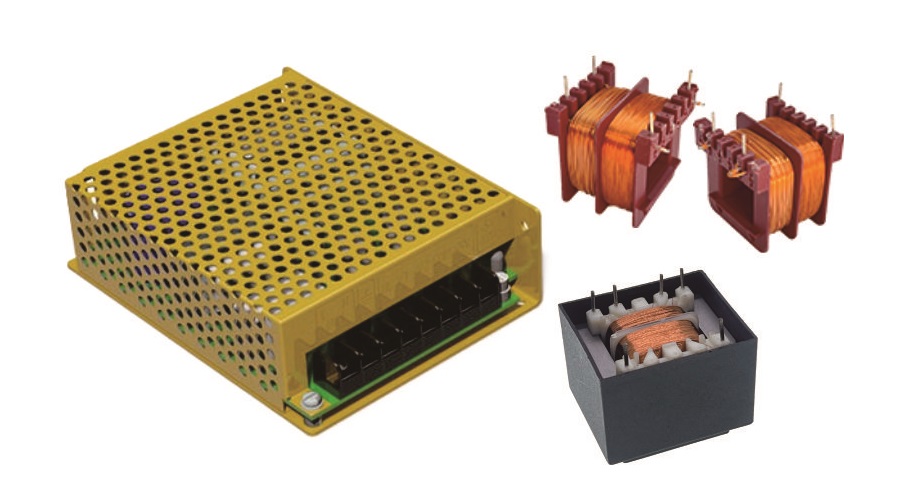

Brushless DC Motors (BLDC) play a pivotal role in electric vehicles, smart appliances, medical devices, and industrial automation, thanks to their high efficiency, long lifespan, and excellent control performance. The quality of a BLDC motor hinges critically on the manufacturing precision and consistency of its stator coils. DETZO has specialized in coil winding equipment for many years, offering fully automated, high-precision solutions for BLDC motor stator winding and assembly. We help your products achieve superior electrical performance and market competitiveness.

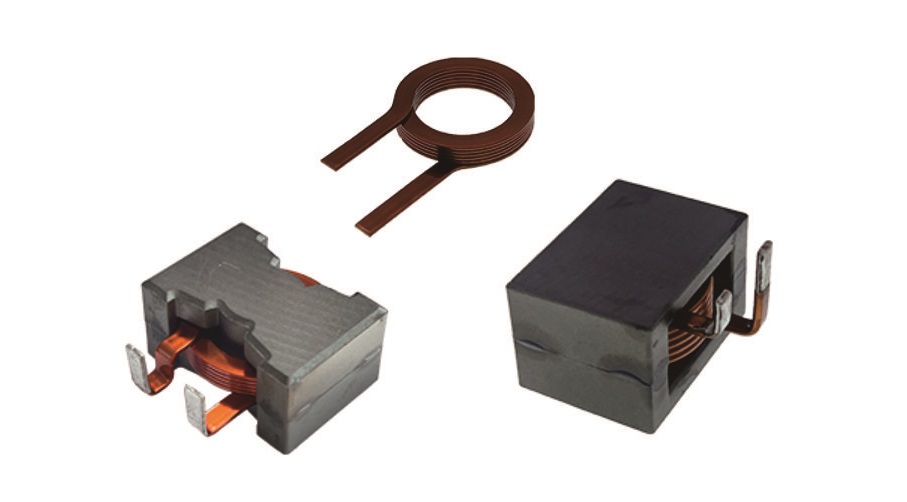

The winding design of a BLDC motor stator coil directly influences the motor's torque ripple, power density, and production efficiency. We provide professional automated equipment support for the market's mainstream winding structures:

01. Concentrated Winding

- Characteristics: Coils are wrapped around only a single tooth pole, resulting in a compact structure.

- Advantages: Features a high slot fill factor and shorter end windings, helping to minimize copper loss.

- DETZO Equipment Requirement: Applicable for high slot/pole count designs, requiring equipment with extremely high positioning accuracy and wire tension control to ensure neat coil arrangement.

02. Distributed Winding

- Characteristics: Coils span across multiple tooth poles, with relatively complex wiring.

- Advantages: Helps to generate a smoother magnetic field, reducing torque ripple and noise, suitable for applications demanding high stability.

- DETZO Equipment Requirement: The winding path is complex, requiring highly flexible, multi-axis, precision winding machines to accurately control the geometry of the distributed coils.

03. Needle/Flyer Winding

- Characteristics: High-speed winding needles (or flyers) pass through the stator bore for winding, suitable for inner-winding stators.

- Advantages: Achieves high levels of automation and production efficiency.

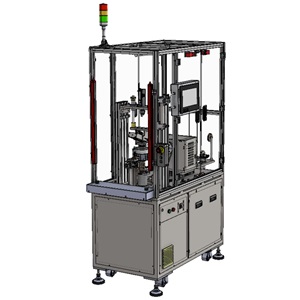

- DETZO Equipment Support: Primarily utilizes the DSW-FM Series Flyer Winding Machines, emphasizing high speed, stability, and accurate wire laying control to ensure high slot filling density.

Choosing DETZO’s automated solutions means you choose efficiency, precision, and reliability. Our equipment is specifically designed to meet the rigorous manufacturing standards of next-generation BLDC motors:

01. Maximized Slot Fill Factor for Enhanced Power Density:

Our motor stator automatic winding machines offer industry-leading precision wire arrangement technology and accurate tension control. This minimizes resistance and significantly boosts the motor's overall efficiency and output power.

02. Full Automation for Guaranteed Quality Consistency:

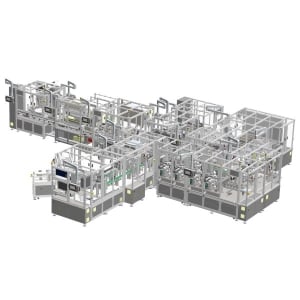

We provide one-stop, customized production lines covering everything from stator feeding and coil winding to lead handling and soldering assembly. Full automation eliminates human error, ensuring the high consistency of every stator coil's turns, phase, and electrical properties.

03. Flexible Adaptability to Diverse Designs:

Whether it's inner winding, outer winding, or various slot/pole combinations, our modular equipment design allows for rapid tool changes (Quick Changeover). This enables your production line to flexibly respond to the market's ever-changing demands for different BLDC motor specifications.

DETZO winding machine can improve the accuracy, efficiency and quality stability of your stator winding manufacturing, helping you meet customer needs more efficiently while reducing production costs. We provide a full range of technical support and training to ensure that customers can fully understand and use our winding machines, and provide quick-response after-sales service.