Application of Transformer Coil Winding Machine

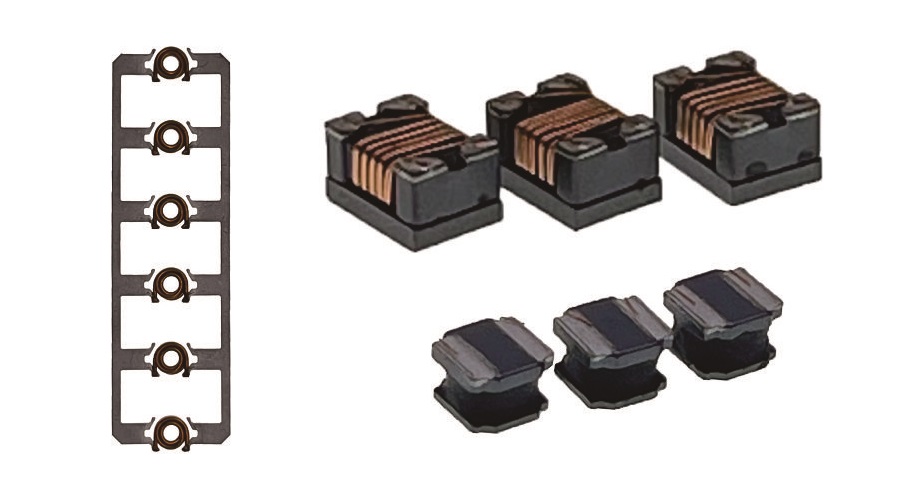

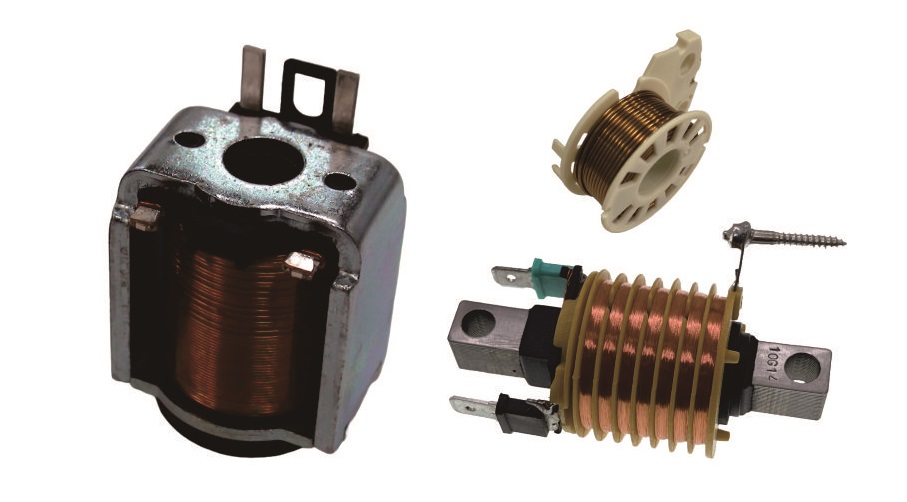

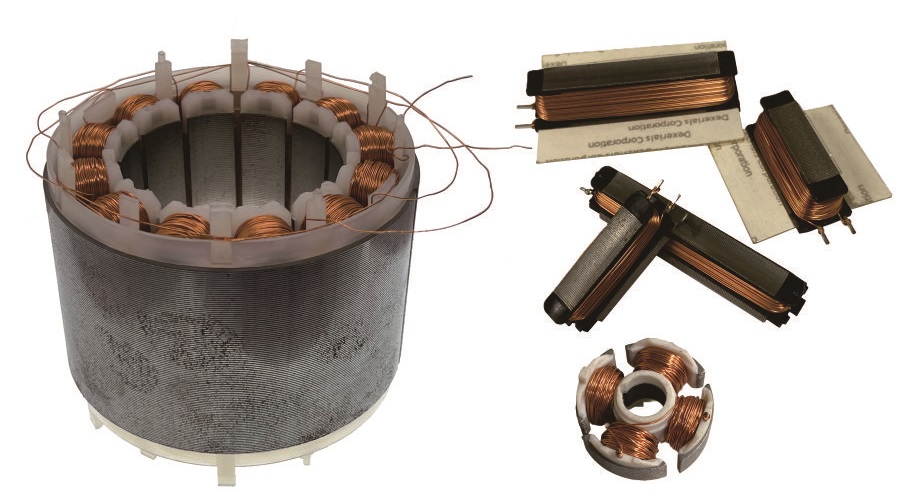

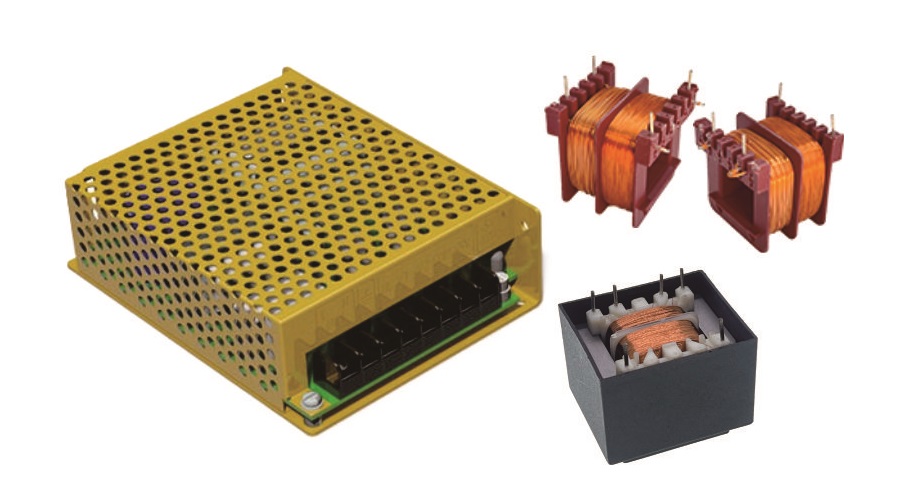

Transformer is a static motor device, consisting of two or more windings, which transforms AC voltage, current and impedance through electromagnetic induction. The invention and application of transformers promoted the development of the electric power industry and became an indispensable and important component of modern society. In addition to transformer coils, inverter coils, rectifier coils, filter coils and even ignition coils are commonly used products in daily life.

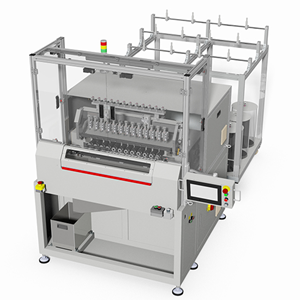

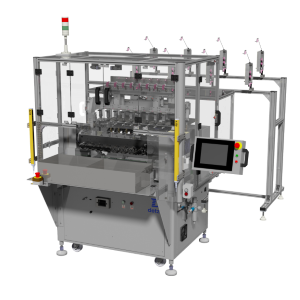

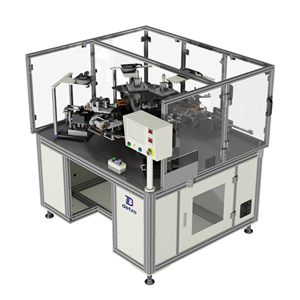

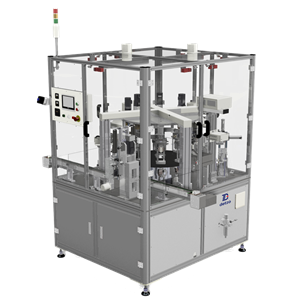

DETZO recommends automated production equipment commonly used for various coil-related products. If you have any related needs, please feel free to contact DETZO.

The main function of the transformer is to change the voltage. Its core part contains the primary and secondary windings, which are composed of wound coils. The transformer coil winding machine can be used to accurately wind the wires or coils on the core of the transformer. These wounds The coil will affect the electrical performance of the transformer and thus the voltage conversion, so the winding machine plays a vital role in manufacturing the transformer.

Different transformer winding designs may affect the transformer's energy conversion efficiency, output voltage stability, load adaptability, etc. The following are three common transformer windings

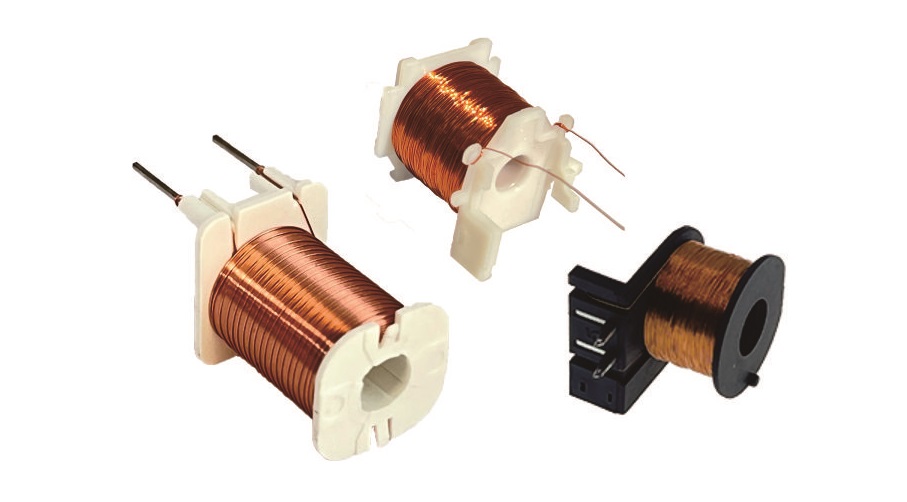

01. Crossover Winding

Crossover winding refers to the winding method in which the primary and secondary windings are placed crosswise on the core, interspersed with each other, and distributed crosswise at different locations on the core. This design method can reduce the mutual inductance between windings, reduce leakage flux, and improve the efficiency of the transformer.

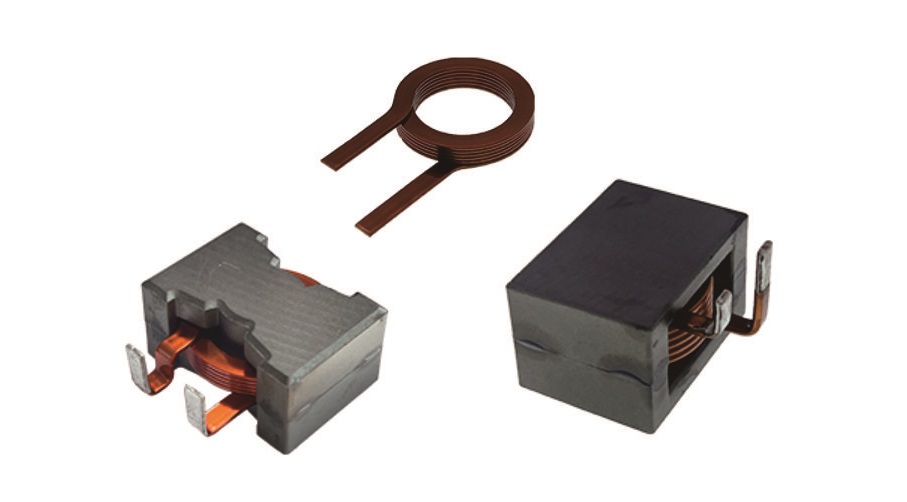

02. Spiral Winding

Spiral winding is to wind the primary and secondary windings in a spiral form on the core to form a spiral winding structure. This winding design is usually used in high-power transformers and can provide better electrical performance and stability.

03. Disc Winding

It is to wind wires or coils around the core of the transformer in a disk-shaped or disc-shaped manner. It can effectively control the electromagnetic field and improve the efficiency and performance of the transformer. It is usually used for some specific types of transformers, such as high-voltage transformers or special Transformers for industrial use.

01. Accuracy

The transformer coil winding machine can accurately control the winding of the coil, ensuring that the size, number of windings and positions of each transformer winding are consistent, improving manufacturing accuracy.

02. Automation Improves Production Efficiency

Compared with manual winding, the winding machine can automatically wind and complete the winding process more quickly, reducing labor costs and manufacturing time, while improving work efficiency and production capacity.

03. Consistency and Stability

Using a transformer coil winding machine to make windings can maintain consistent quality and stability, reducing variability in the transformer manufacturing process and ensuring stable product quality.

DETZO transformer winding machine can improve the accuracy, efficiency and quality stability of your transformer winding manufacturing, helping you meet customer needs more efficiently while reducing production costs. We provide a full range of technical support and training to ensure that customers can fully understand and use our winding machines, and provide quick-response after-sales service.