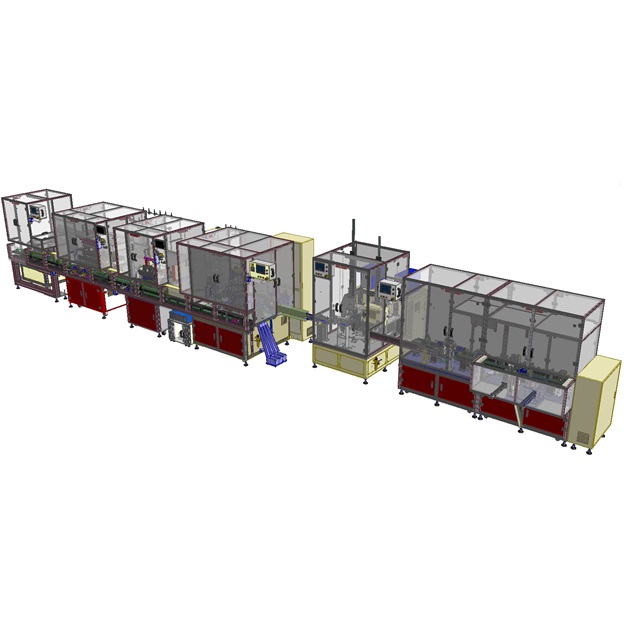

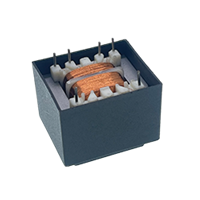

Custom Low Frequency Transformer Coil Production Line

Customized model 03

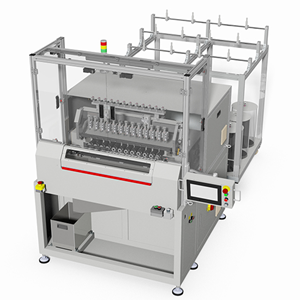

Low Frequency Transformer Coil: Automatic Production Line

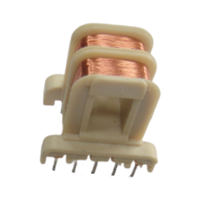

The DETZO Low Frequency Transformer Coil Production Line is engineered for low-frequency transformers, featuring dedicated winding stations for both thick and fine wire, integrating assembly, and final testing.

Precision engineering for low-frequency transformer production

DETZO Turnkey Solutions

Low Frequency Transformer Coil: Process Flow

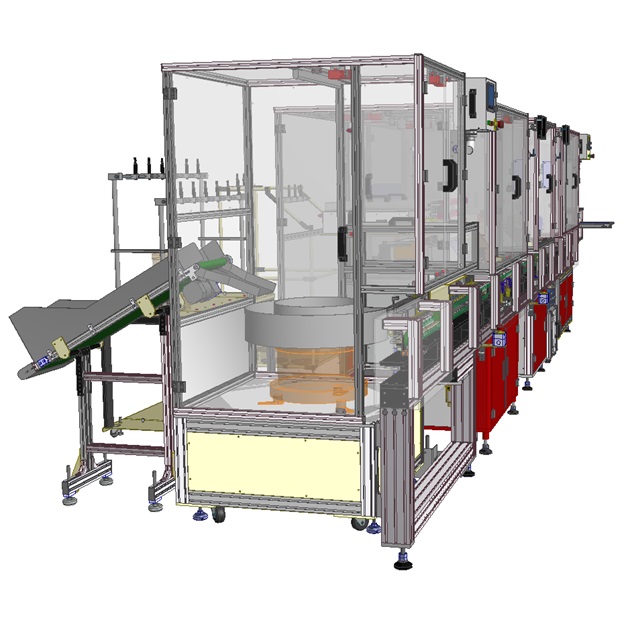

STEP 01 | Feeding & Hybrid Winding Stations

- A. Vibrating Plate Automatic Bobbin Feeder: Features a specialized sorting mechanism to ensure bobbins are oriented and fed continuously, minimizing production downtime.

- B. DSW-6012PT Winding Machine (Fine Wire): Equipped with a high-sensitivity tension control system for primary windings, ensuring wire integrity even during high-speed, high-turn counts.

- C. DSW-6006P Winding Machine (Thick Wire): Engineered with high-torque motors to handle heavy secondary windings, ensuring uniform layering and optimal current conductivity.

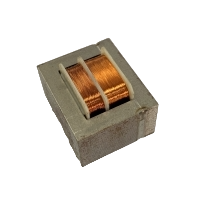

STEP 02 | Integrated Soldering & Core Assembly

- D. 8-station Soldering & Testing Machine: A rotary system that integrates fluxing, temperature-controlled dip soldering, and continuity testing in a single synchronized cycle.

- E. Silicon Steel Sheet Assembly Machine: Automated EI core lamination with precise alignment to minimize air gaps and maximize magnetic flux efficiency.

- F. TIG Welding Machine: Utilizes advanced welding techniques to stabilize the core structure, preventing noise and vibration caused by magnetic hysteresis.

STEP 03 | Final Quality Validation

- G. Testing Machine: Comprehensive inspection of inductance, insulation, and dielectric strength, ensuring every transformer meets rigorous safety and performance standards.