High Frequency Transformer Coil Production Line

Customized model 04

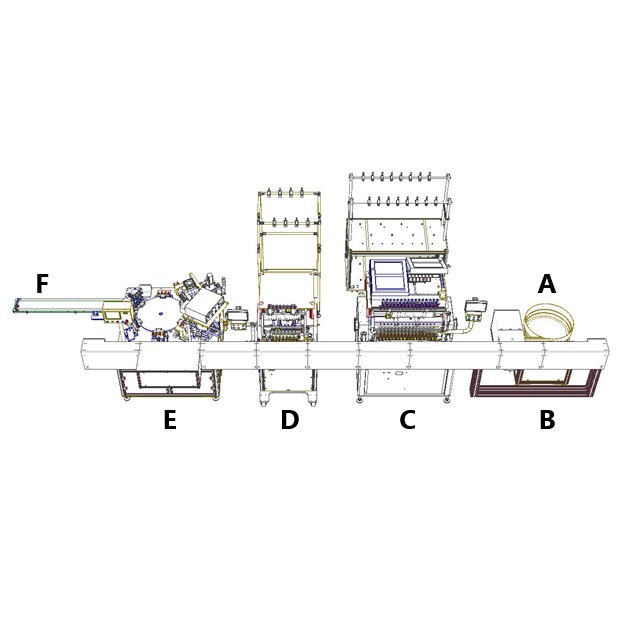

HF Transformer Coil: Automatic Production Line

The DETZO High Frequency Transformer Coil Production Line is engineered for high-frequency transformer coil production, featuring dedicated stations for both fine and thick wire winding. This line integrates a 6-station soldering and testing system for peak reliability.

Dual-station winding and 6-station testing for maximum reliability

DETZO Turnkey Solutions

HF Transformer Coil: Production Process Flow

STEP 01 | Feeding & Conveying

- A. Vibrating plate automatic bobbin feeding machine

- B. Servo conveyor mechanism - Precision indexing between stations

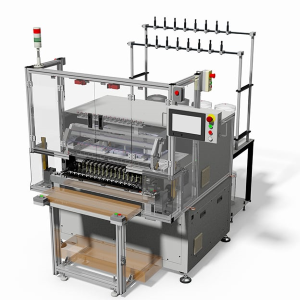

STEP 02 | Hybrid Automatic Winding

- C. DSW-4216PTN Winding Machine - Dedicated for Fine Wire processing

- D. DSW-4208P Winding Machine - Dedicated for Thick Wire processing

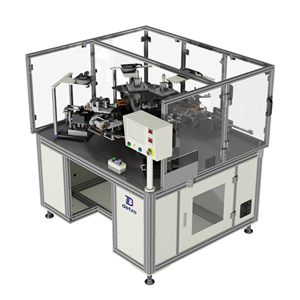

STEP 03 | Testing & Output

- E. 6-station soldering & testing machine

- F. Finished product output - Connecting with back-end process