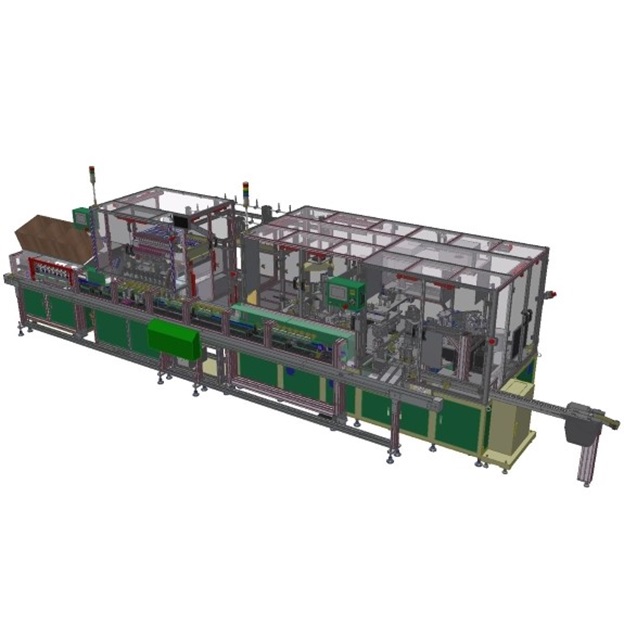

Automatic Electromagnetic Switch Coil Production Line

Customized model 02

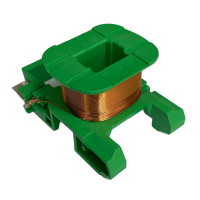

Electromagnetic Switch Coil: Automatic Production Line

DETZO Electromagnetic Switch Coil Production Line is engineered for electromagnetic switch coil production, combining flexible manual loading with high-efficiency automated winding, soldering, and comprehensive testing.

Combined 8-station processing for high-quality electromagnetic components

DETZO Turnkey Solutions

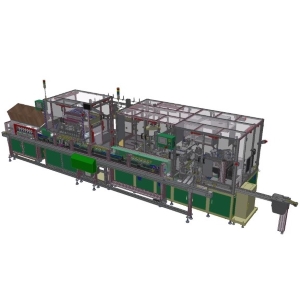

Electromagnetic Switch Coil: Process Flow

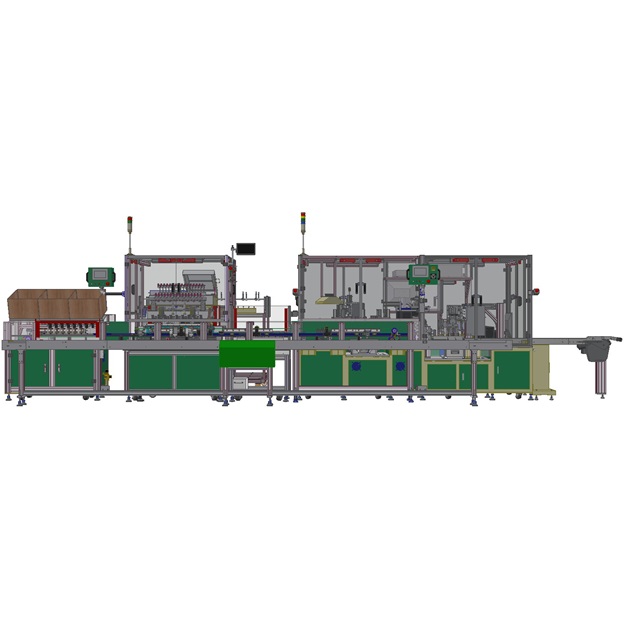

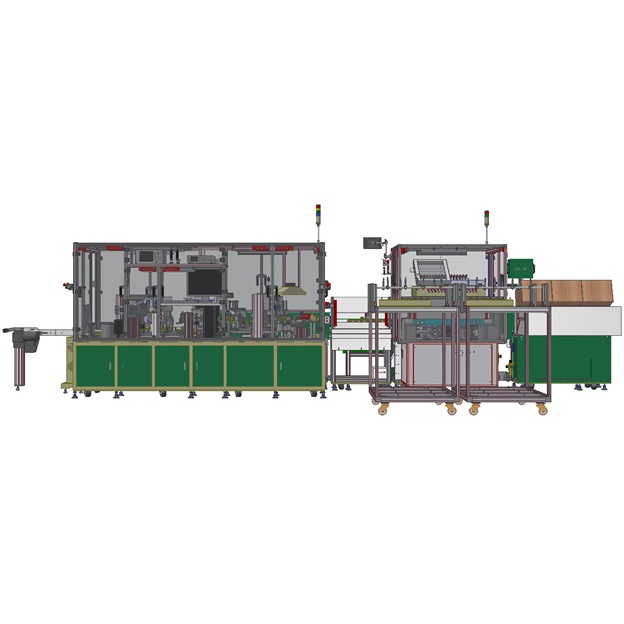

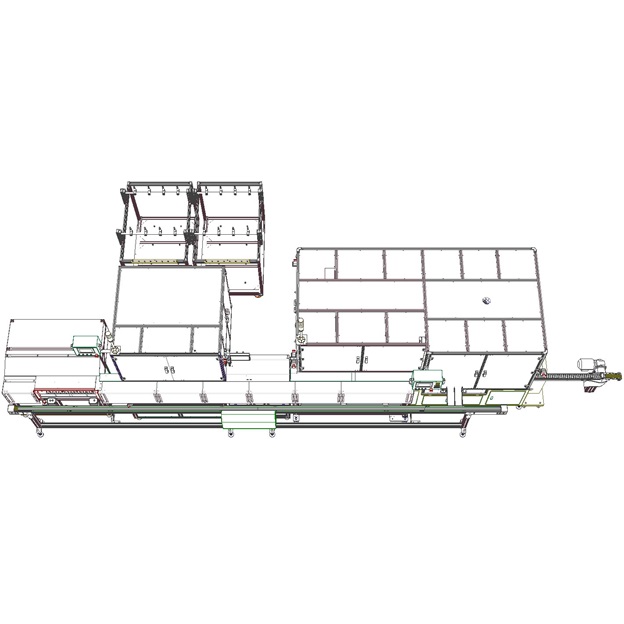

STEP 01 | Flexible Feeding & Winding

- A. Manually loading station: Allows high process flexibility for various bobbin specifications.

- B. DSW-8008NPT Automatic winding machine: High-speed winding core ensuring precise wire layering and optimal electromagnetic performance.

STEP 02 | 8-Station Processing Line

- C. 8-station soldering machine: Synchronized multi-station processing with precise fluxing and temperature-controlled soldering.

- D. 8-station testing machine: Comprehensive electrical validation station ensuring every coil meets strict quality standards.

STEP 03 | Final Output

- E. Finished product output / unloading station: Final stage for collecting certified finished products.