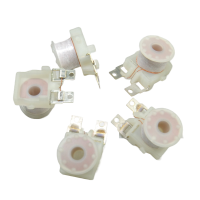

Custom Electromagnetic Switch Coil Production Line for Switch

Customized model 01

Magnetic Switch Coil: Automated Production Line

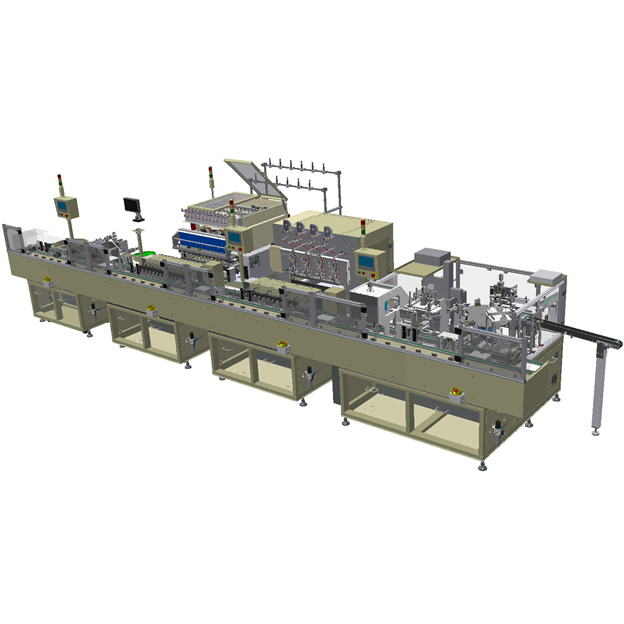

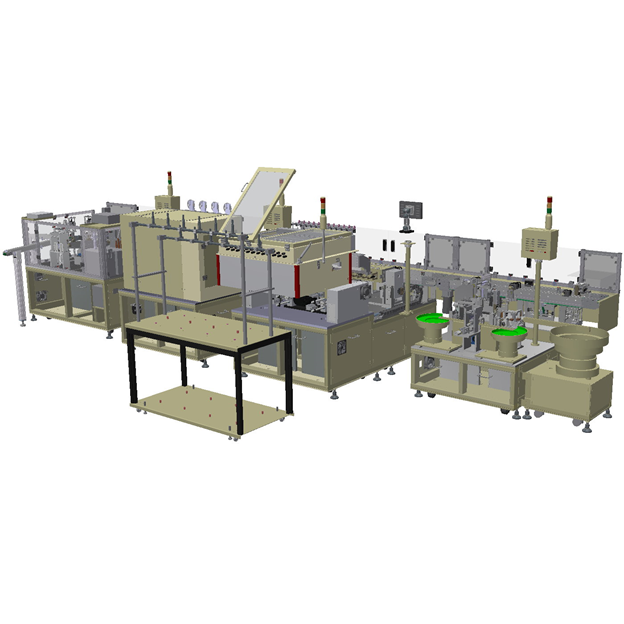

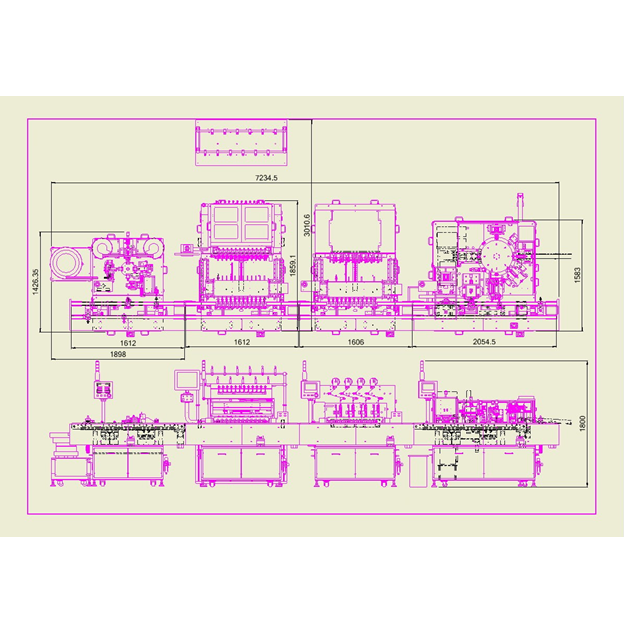

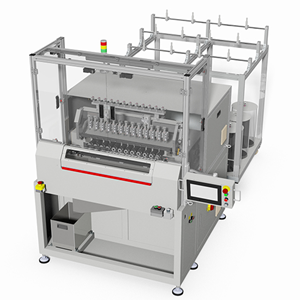

DETZO Electromagnetic Switch Coil Production Line is a flagship automated solution designed for high-quality Starter Coils, Electromagnetic Switch Coils, and Relay Coils. This turnkey line integrates vibratory plate feeding, precision pin insertion, high-speed winding, taping, and an 8-station welding/testing process to ensure maximum production yield.

Delivering the most precise and reliable automated winding technology to the global market

DETZO Turnkey Solutions

Fully Automated Process Flow

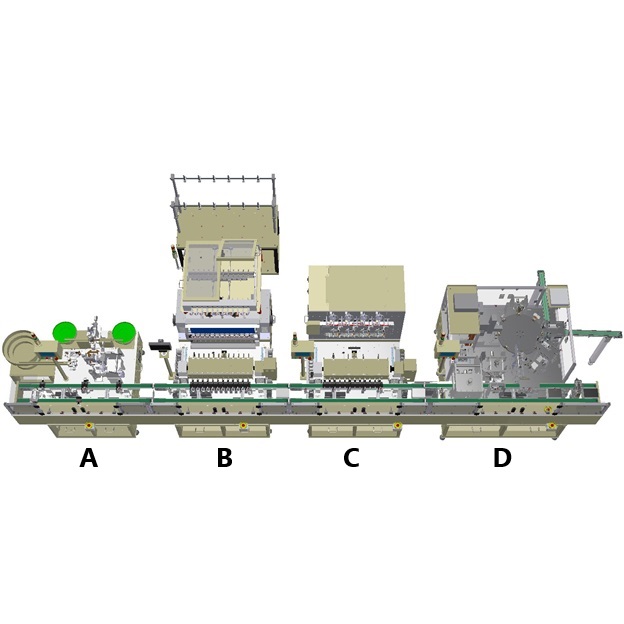

STEP 01 | Pin Insertion Process

- A. 4-station automatic pin inserting machine - Automated bobbin supply and precision pinning.

- • A1. Vibrating plate feeder (plastic) + Bobbin feeding station: Automated bobbin supply.

- • A2. Vibrating plate feeder (left and right pin) + Pin insertion station: Precision pin assembly.

- • A3. Pin height detection + NG unloading station: Quality check for pins.

- • A4. Bobbin change direction and Loading station: Alignment for winding.

STEP 02 | High-Speed Winding & Taping

- B. DSW-6012PT automatic coil winding machine + Tooling revolver mechanism - Precise 12-spindle winding and terminal pinning.

- C. DSW-TAPE1804 automatic taping machine + Tooling revolver mechanism - Automated insulation for structural stability.

STEP 03 | Soldering, Testing & Post-treatment

- D. 8-station welding machine - Integration of precision soldering and 100% electrical validation.

- • D1. Pin pre-clamp station: Securing wire to pins.

- • D2. Residual wire cleaning station: Automated trimming of waste leads.

- • D3. Bobbin orientation station: Alignment for soldering accuracy.

- • D4. Bobbin shortage detection station: Confirmation of part presence.

- • D5. Auto welding station (Left/Right): Automated terminal dipping and soldering.

- • D6. Reserve station: Scalable for future functions.

- • D7. Wire tension release station: Neutralizing internal winding stress.

- • D8. Resistance testing station: 100% DCR electrical validation.

STEP 04 | Final Quality Sorting

- • D9. OK unloading station (Conveyor): Pass product output.

- • D10. NG unloading station (Collecting Box): Segregation of defects.