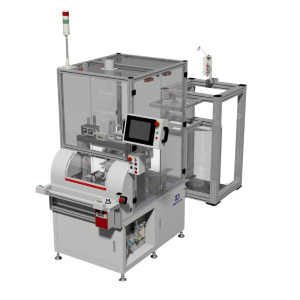

Automatic Vertical Coil Winding Machine with Heater and Stripper

DSW-001PTNC

Feature

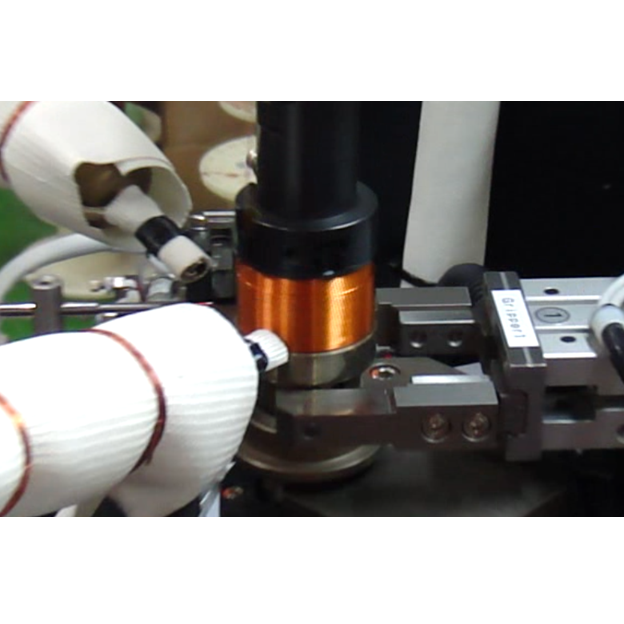

- The Keyence system is combined with an AC servo motor drive system for precise positioning.

- Intuitive and simple operation, with 10" HMI to edit programs in dialogue mode, easy to use.

- Special quickly change winding tooling.

- With automatic loading and unloading function (except special models), increase production capacity.

- Automatic pin wrapping & residual wire removal system.

- 120 sets of programs can be stored, and program switching is fast.

- Hierarchical management and password storage function to prevent non-related personnel from modifying the program.

- The structure is simple, the control is easy, and the maintenance is convenient.

Specification

| No. of spindle | 1 Spindle |

|---|---|

| Applicable wire diameter | Ø0.02 ~ Ø1.20mm |

| Spindle speed | Max. 3000rpm (CW/CCW) |

| Angular accuracy | +/-0.5° |

| Movement of Nozzle | X-Axis 100mm (Front/Back) |

| Y-Axis 80mm (Left/Right) | |

| Z-Axis 70mm (Up/Down) | |

| Nozzle movement accuracy | 0.01mm |

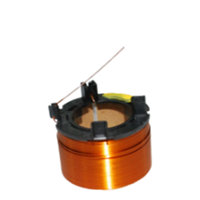

| Winding diagonal (max.) | 45mm |

| Winding range (max.) | 50mm |

| Controller | PLC 4-axis control |

| Storage | Memory card |

| Power supply | 1Φ 220Vac |

| Rated frequency | 50 ~ 60Hz ±1% |

| Power consumption | 3KW |

| Air pressure demand | 0.4 ~ 0.6Mpa |

| Machine dimensions | 1600(L) x 900(W) x 2000(H)mm |

| Machine weight | 800kg ±10 |

Optional Item